Inductive proximity sensor

Inductive proximity sensor is a non-contact detection device, and its working principle is based on electromagnetic induction principle. The following is a detailed introduction to the inductive proximity sensor:

一、 Working principle

The inductive proximity sensor contains a high-frequency oscillation circuit and a detection circuit. The high-frequency oscillation circuit generates an alternating magnetic field, and when a metal object approaches the sensing surface of the sensor, an eddy current will be generated inside the metal object. The magnetic field generated by eddy current interacts with the original magnetic field inside the sensor, which causes the frequency or amplitude of the high-frequency oscillation circuit to change. The detection circuit is responsible for detecting this change, and converting it into an electrical signal to input the book, so as to realize the detection of metal objects.

二、 Composition structurehttps://www.sopsensor.com/product-list/proximity-sensor

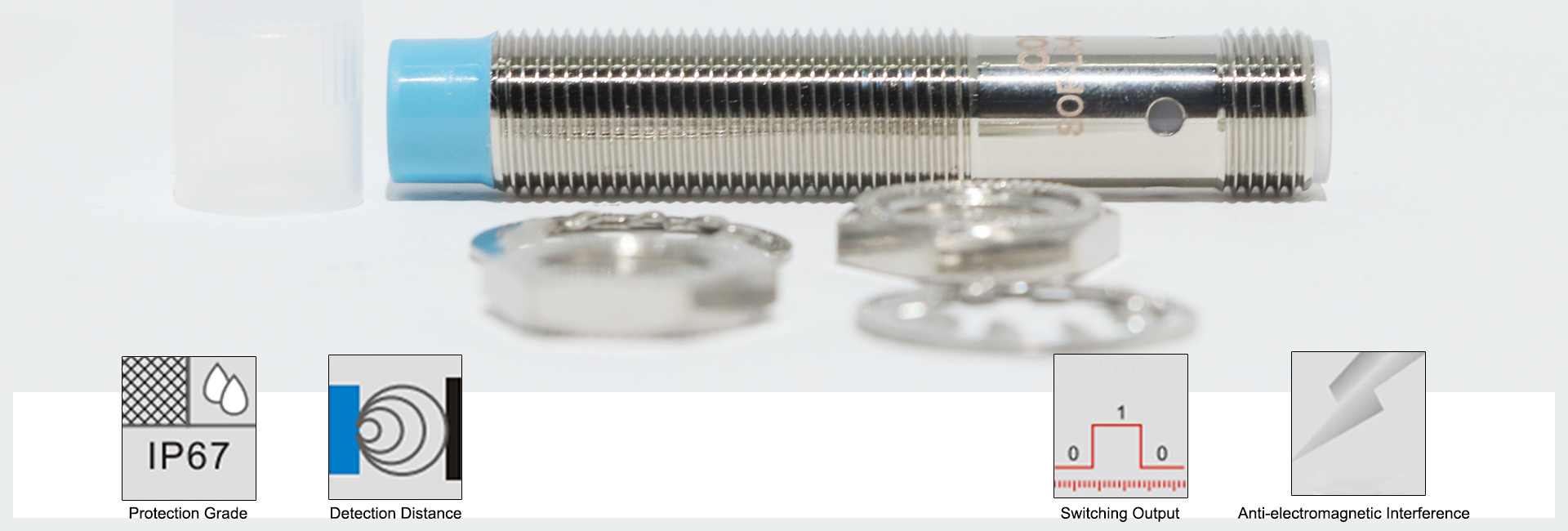

Inductive proximity sensor is mainly composed of coil, oscillator, switch circuit and amplifier output circuit. Among them, the coil is used to generate the zi field, the oscillator is used to generate the alternating magnetic field, and the switching circuit and the amplification output circuit are used to process the detected signal and output the switching signal.

三、 Characteristics and advantages

1. Non-contact detection: The inductive proximity sensor can detect without touching objects, thus avoiding the possible wear and damage caused by traditional contact detection.

2. High sensitivity and quick response: Due to the principle of electromagnetic induction, the sensor can quickly detect the approach of metal objects and output corresponding electrical signals.

3. Strong environmental adaptability: The inductive proximity sensor can withstand common conditions in industrial fields, such as dust, dirt and humid environment.

4. Long service life: Since there are no moving parts, the sensor has a longer service life and higher reliability.

四、Application field

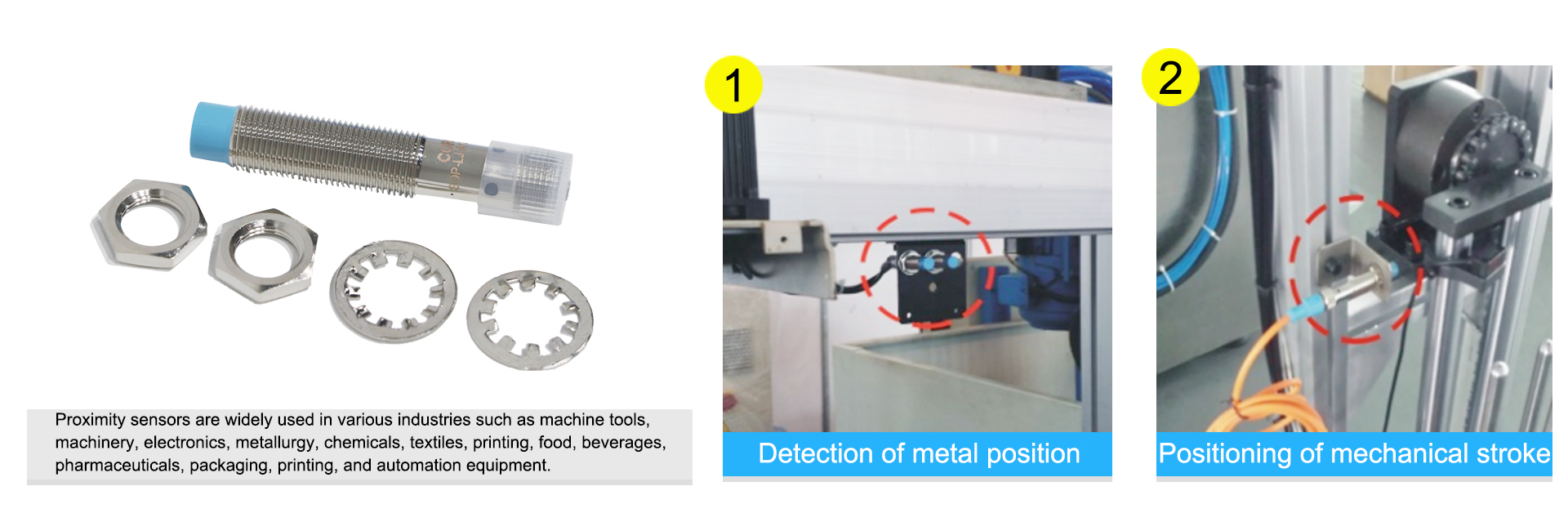

Inductive proximity sensors are widely used in industrial automation, robotics, machinery manufacturing and other fields. For example, in the automatic production line, sensors can be used to detect the position, existence and motion state of the workpiece, so as to realize the automation and intelligence of the production process. In addition, it can also be used to detect the speed of sprocket teeth in textile, chemical fiber, machine tool, machinery, metallurgy, locomotive and automobile industries, the speed and distance of chain conveyor belt, and the control of automobile protection system.

五、 Matters needing attention

1.Detection range: The detection range of inductive proximity sensor is usually affected by the material, shape and size of metal objects. Therefore, when selecting sensors, it is necessary to make appropriate selection according to actual application scenarios.

2. External interference: The sensor may be subjected to electromagnetic interference from motors, frequency converters and other equipment, resulting in a decline in detection performance. Therefore, in the process of installation and use, corresponding anti-interference measures need to be taken.

3. Installation and maintenance: In order to ensure the normal operation of the sensor and prolong its service life, it is necessary to install and maintain it correctly according to the instructions. At the same time, it is necessary to pay attention to avoid the influence of mechanical shock and vibration on the sensor.