-

01-15 2026

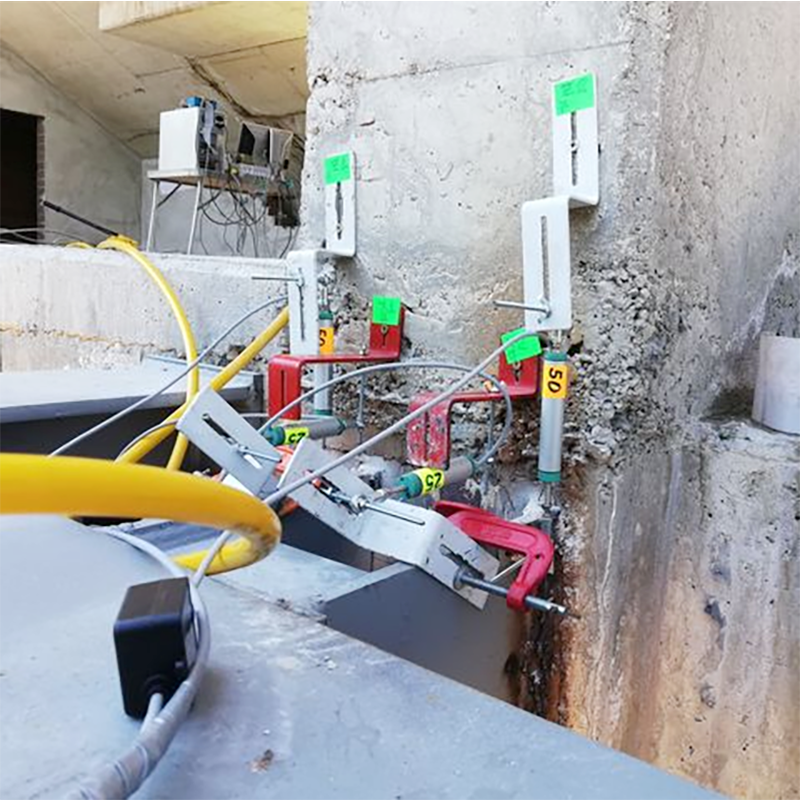

Application of SOP linear displacement sensor in tunnel

Linear displacement sensor is a kind of non-electric measurement sensor which is widely valued and applied at home and abroad at present. It consists of a heat-treated vibrating wire detection element, and a spring with one end connected to the vibrating wire and the other end connected to the sliding pull rod to eliminate stress. With the pull of the sliding pull rod, the spring begins to extend and causes the tension of the vibrating string to increase, and the vibration frequency of the steel string also changes, and the tension is proportional to the extension of the spring. Therefore, the change of displacement can be realized by measuring the tension of the steel string, that is, the change of the vibration frequency of the steel string.

-

01-14 2026

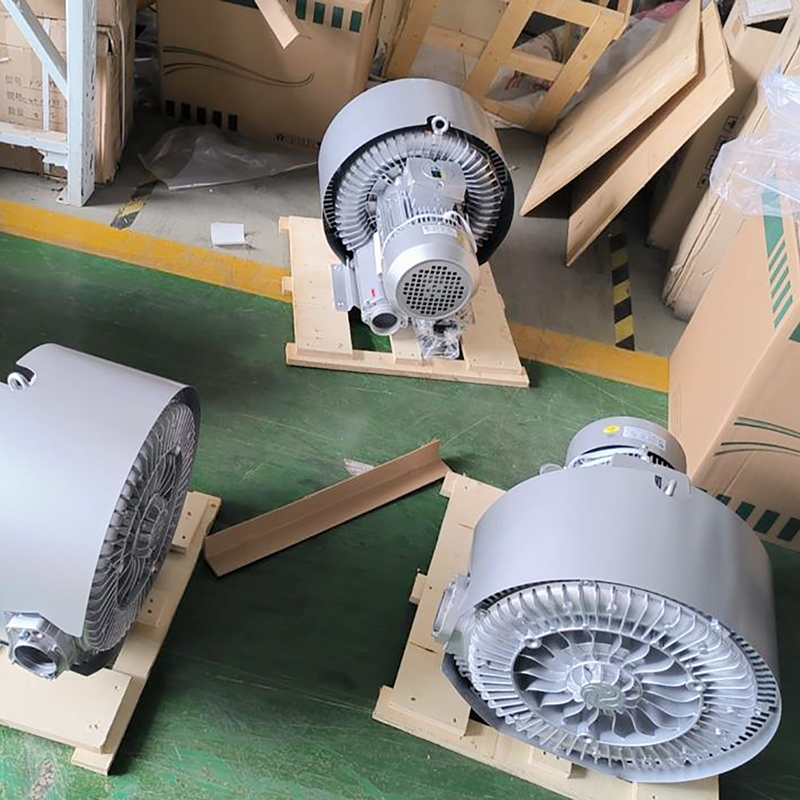

Benefits and Advantages of Twin-impeller Side-channel Blowers in Wastewater Aeration

Modern wastewater treatment plants are judged by two yardsticks: the quality of the effluent and the size of the electricity bill. The twin-impeller side-channel blower, epitomised by the 2LG720-7HH26, addresses both challenges in a single, compact package. With two dynamically balanced impellers mounted on one shaft, the unit behaves like two blowers in series, generating a continuous, pulse-free flow that dissolves oxygen far more efficiently than conventional single-stage machines.

-

01-14 2026

Application of linear displacement sensor in intelligent agricultural machinery matching

Sensor is a kind of equipment that can sense environmental changes and automatically collect, process and transmit data. Intelligent agricultural machinery is mainly integrated in seeders, harvesters and other devices, supporting automatic driving and operation monitoring, and combining sensors and agricultural machinery equipment to realize the automation and intelligence of agricultural machinery operation. For example, using the controllability of sensors to ensure the accuracy of the driving path of agricultural machinery and avoid the collision of agricultural machinery at high speed and damage to agricultural products.

-

01-08 2026

Application of spoke load cell

Spoke force sensor is also the most commonly used sensor in our industrial practice. Because of its advantages of shock resistance, vibration resistance, high precision, high stability and wide working temperature range, it is widely used in many industries. So, how much do you know about the main principles and principles of spoke force sensor structure design? Next, let's understand the main principles and principles of structural design of spoke force sensor. Main principles and principles of structural design of spoke weighing sensor; Spoke force sensor First, the main principles of structural design of spoke force sensor

-

01-08 2026

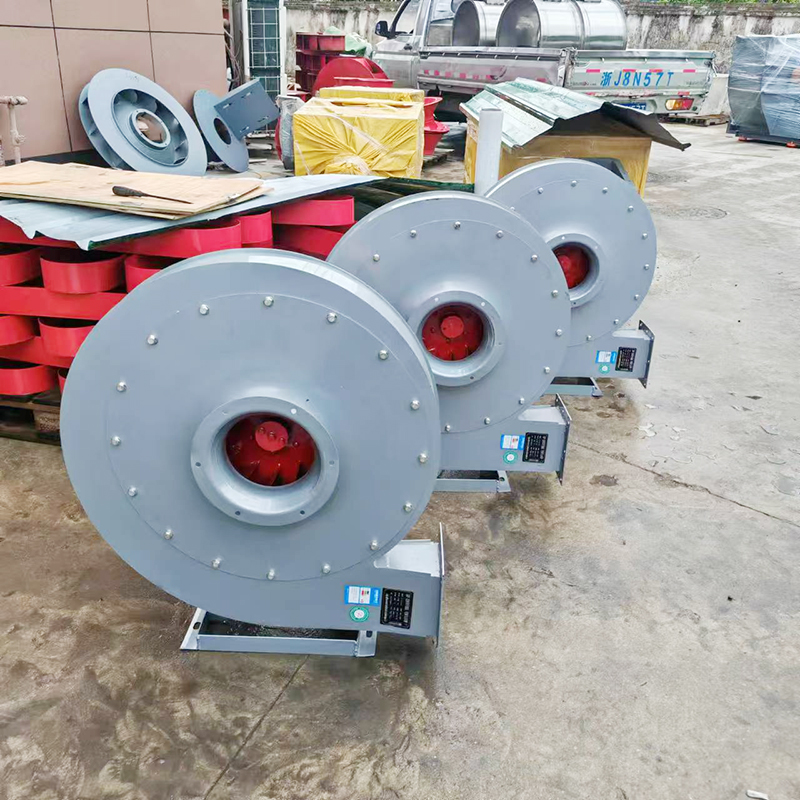

Centrifugal Fans: The Backbone of Factory Ventilation Systems

In the realm of industrial production, maintaining a safe an efficient working environment is paramount, and factory ventilation stands out as a critical factor in achieving this goal. Among the various ventilation equipment available, centrifugal fans have emerged as the workhorse, widely adopted across diverse manufacturing sectors for their superior performance and adaptability.

-

12-31 2025

Global Linear Sensor Market: An In-Depth Analysis

The global linear sensor market is a critical component of the broader industrial automation and precision measurement landscape. Characterized by its essential role in enabling high-accuracy positional feedback, this market is experiencing steady growth, driven by the relentless march of Industry 4.0, the expansion of robotics, and the escalating demand for quality control across manufacturing sectors.

-

12-30 2025

Pressure sensors are commonly used in industrial intelligent compressors.

Pressure sensor is commonly used in industrial intelligent compressor: industrial numerical control compressor has strong versatility. It adds pressure sensor to hydraulic press, and converts it into pressure loading value, digital display, over-limit, acousto-optic alarm and stop signal through data acquisition and system processing composed of microcomputer, so as to realize automatic control of pressure loading force, load display controller, clear display, accurate control, fast response and stable and reliable work. Replace different sensors and application software for forging equipment with different tonnage. Characteristics of pressure sensor used in intelligent numerical control compressor control system; CNC intelligent press control system, such as CNC intelligent pressure and force position control software, EXLAR electric cylinder, force position sensor, etc

-

12-30 2025

Medium-Pressure Fans: The Unsung Heroes Powering Modern Industry

In the intricate ecosystem of industrial operations, where every component plays a pivotal role in ensuring efficiency, reliability, and safety, medium-pressure fans stand out as unsung heroes. These versatile machines, designed to generate air pressure ranging from 1.5 kPa to 10 kPa, bridge the gap between low-pressure ventilation systems and high-pressure compressors, making them indispensable across a diverse array of sectors. From manufacturing plants and wastewater treatment facilities to food processing units and renewable energy projects, medium-pressure fans deliver consistent performance that keeps operations running smoothly, reduces energy costs, and minimizes environmental impact.

-

12-27 2025

Application of spoke weighing sensor in weighing system of material tank

Tanks are usually subject to climatic conditions or production-related influences. When building new open-air materials (silos and coal bunkers), the building regulations must be observed. If dangerous goods are loaded and it is expected to be operated by forklift, the tank on the roof should also be protected from lifting. Weight distribution When the tank is supported on three bearing points, and each bearing point is provided with a sensor, the best sensor regulation for determining the weight of the tank can be achieved. For a vertical or suspended cylindrical tank, the best uniform condition is met when the three sensors are equidistant from the vertical axis of the tank and 120 degrees from each other on the plane.

-

12-23 2025

Application case of pressure sensor in injection mold

Today's competitive environment requires mold manufacturers not only to make molds, but also to be versatile when facing many questions raised by users, such as when users ask, what shrinkage rate should we use? "Sometimes, they need to act as plastic experts. When asked how high the mold temperature is, what is the heating rate? At that time, they need to be craftsmen: and when asked, are there any other ways to demould products? ",they need to act as automation engineers.