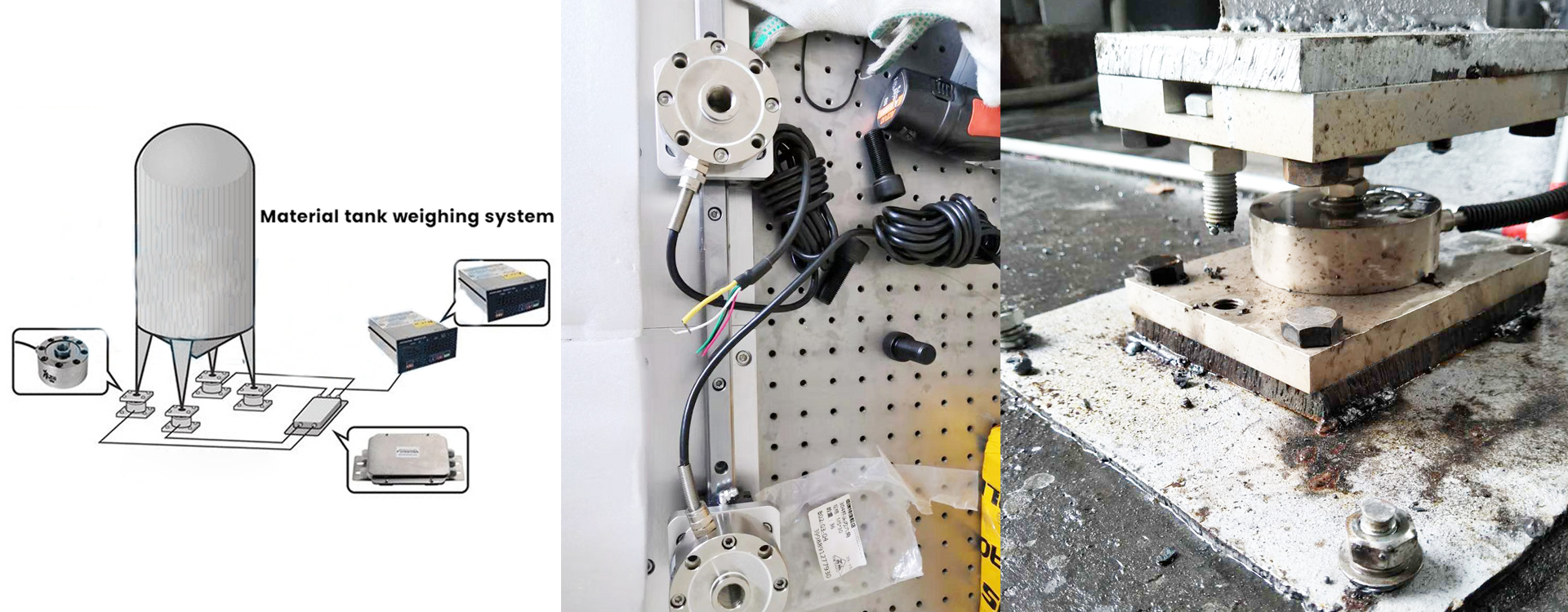

Application of spoke weighing sensor in weighing system of material tank

Application of spoke weighing sensor in weighing system of material tank

Tanks are usually subject to climatic conditions or production-related influences. When building new open-air materials (silos and coal bunkers), the building regulations must be observed. If dangerous goods are loaded and it is expected to be operated by forklift, the tank on the roof should also be protected from lifting. Weight distribution When the tank is supported on three bearing points, and each bearing point is provided with a sensor, the best sensor regulation for determining the weight of the tank can be achieved. For a vertical or suspended cylindrical tank, the best uniform condition is met when the three sensors are equidistant from the vertical axis of the tank and 120 degrees from each other on the plane.

If not all supports in a device are equipped with sensors, the uneven distribution of support load is more suitable. If the tank is supported by four or more points, sensors must be considered at all bearing points. The center of gravity of the tank with full load should be lower than the support point of the tank as far as possible. The position of the center of gravity changes with the height of the filling quantity, and the center of gravity moves on a vertical line, so it is possible to manufacture weighing equipment with one sensor. If the center of gravity moves laterally with the center line due to the change of the filling, all support points should be equipped with sensors.

Interfaces such as loading and unloading of tanks often require loading and unloading of other interfaces, such as loading and unloading of tank contents, auxiliary equipment such as electronics, wave pressure or air pressure of tanks. The loading and unloading interface of the tank can produce the influence of additional force, which leads to the error of the measurement accuracy of the species. When connecting the inflexible rigid pipe, the material badger is connected with a horizontal pipe as long as possible, and the stress acting on the sensor is relatively small, which is not important to the measurement accuracy. A few sections of flexible connecting pipes can replace the long horizontal pipe, thus avoiding additional force. Other possibilities to reduce additional force are to configure arc pipes, which are generally compensated by corrugated pipes in the case of vertical pipe introduction. Pressure load In closed equipment, the system pressure has an influence on the weighing results, especially in the chemical industry, when the pipes are vertically connected in the container, there is an additional force that directly enters the measurement. Its influence corresponds to the product of the pressure and the transverse surface of the pipeline, so it is best to use a horizontal connecting pipe.