Application case of pressure sensor in injection mold

Application case of pressure sensor in injection mold

Today's competitive environment requires mold manufacturers not only to make molds, but also to be versatile when facing many questions raised by users, such as when users ask, what shrinkage rate should we use? "Sometimes, they need to act as plastic experts. When asked how high the mold temperature is, what is the heating rate? At that time, they need to be craftsmen: and when asked, are there any other ways to demould products? ",they need to act as automation engineers.

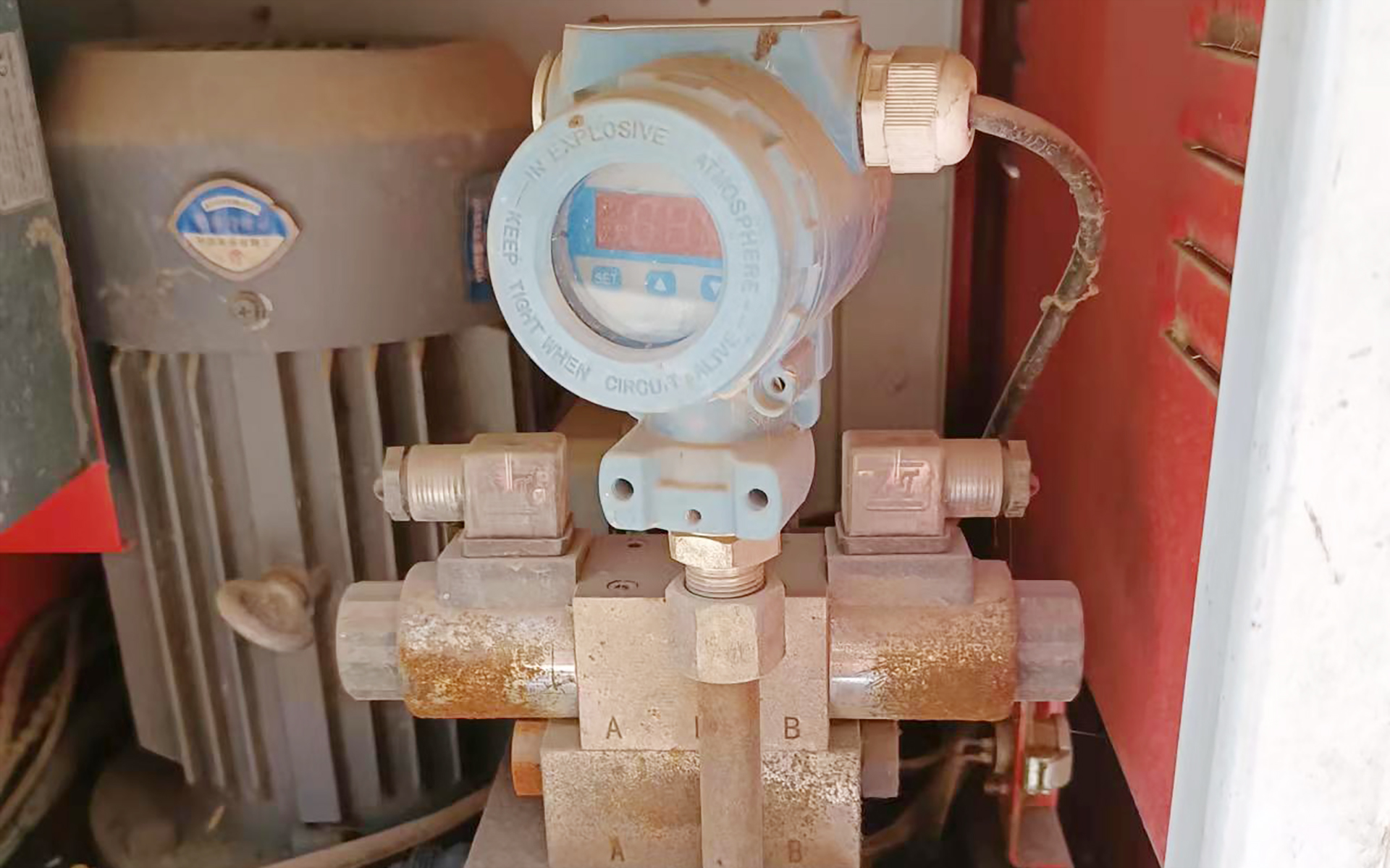

In the past, such generalists did not exist at all. Now, with the role of pressure sensors, mold manufacturers can have this ability. This pressure sensor can be installed in the nozzle, hot runner system, cold runner system and exhausted mold cavity of the injection molding machine, and it can measure the plastic pressure somewhere between the nozzle and the mold cavity of the injection molding machine during injection molding, mold filling, pressure maintaining and cooling.

The data can be recorded in the monitoring system to adjust the molding pressure in real time, and check or eliminate the faults in the production process after molding. It is worth mentioning that the collected pressure data can become the general process parameters for this mold and this material, in other words, the data can guide the production on different injection molding machines (using the same mold).

Only the case where the pressure sensor is installed in the mold cavity is discussed here. Types of pressure sensors At present, there are two types of pressure sensors used in the mold cavity, namely, the flat type and the indirect type. The flat type sensor is inserted into the mold cavity by drilling a mounting hole behind the mold cavity, and its top is flush with the surface of the mold cavity, and its cable passes through the mold and is connected with the monitoring system interface located on the outer surface of the mold.

The advantage of this sensor is that it will not be disturbed by the pressure during demoulding, but it is easy to be damaged at high temperature, which makes it difficult to install. Indirect sensors can be divided into two types: sliding type and button type. They can both transmit the pressure exerted by plastic melt on ejector or fixed pin to the sensor on the ejector plate or movable template of the mold. Sliding type sensors are usually installed on the ejector plate under the existing ejector pin.

When high-temperature molding is carried out, or low-pressure sensors are used for small ejector pins, sliding type sensors are usually installed on the movable template of the mold. At this time, the ejector pin acts through the ejector sleeve or another transition pin is used.

The transition pin has two functions. First, it can protect the sliding sensor from the interference of demoulding pressure when using the existing ejector. Another function is that when the production cycle is short and the demoulding speed is fast, it can make the sensor not be affected by the rapid acceleration and deceleration of the ejector plate.

The size of the ejector pin at the top of the sliding sensor determines the size of the required sensor. When multiple sensors need to be installed in the mold, the mold designer needs to use the ejector pin with the same size for them to avoid the setting error or adjustment error of the molder. Because the ejector pin is used to transmit the pressure of the plastic melt to the sensor, different products need to use ejector pins with different sizes.

Generally speaking, the button sensor should be fixed in a certain recess in the mold, so the installation position of the sensor must be the most interesting position for the processing personnel.

If you want to disassemble this sensor, you must open the template or make some special designs on the structure in advance. Depending on the position of the button sensor in the mold, it may be necessary to install the cable junction box on the template. Compared with the sliding sensor, the pressure reading of the button sensor is reliable, because the button sensor is always fixed in the cavity of the mold, unlike the sliding sensor, which can move in the drilling hole. Therefore, button sensors should be used as much as possible.