Do you want to use LVDT displacement sensor in automobile parts inspection?

Do you want to use LVDT displacement sensor in automobile parts inspection?

For the inspection of automobile parts, the size inspection should be the most important, and LVDT displacement sensor (differential transformer displacement sensor) must be used to detect and control the size. As a displacement sensor with strong environmental adaptability, high precision and durability, LVDT displacement sensor is the first choice in parts inspection system. So what is the specific application of LVDT displacement sensor in automobile parts inspection?

In the production of automobile industry, the application of automatic inspection technology for parts can not only improve production efficiency, but also reduce the influence of human factors on quality, and the core component of automatic inspection is LVDT displacement sensor. LVDT displacement sensor is a device that converts non-electric physical quantities into electric quantities. The electrical signals measured by LVDT displacement sensor are transmitted to the computer through the acquisition card, and the computer analyzes and processes them in order to issue corresponding action instructions. In the production process of automobile parts, a "computer aided detection system" can be formed by LVDT displacement sensor and computer to realize automatic detection. The technical basis of the system is a high-performance LVDT displacement sensor, and the production quality is monitored by computer-aided detection at each production stage and data exchange between LVDT displacement sensor and computer.

This is a complex system, and its realization mainly depends on the "computer-aided detection system". It uses the combination of computer and PLC to apply various high-performance LVDT displacement sensors to the detection terminal, so that the parts can be inspected in all directions, and then the application of automatic detection can be realized with the help of advanced automatic control system. Using the cooperation of LVDT displacement sensor, computer and PLC to adjust online, at the same time, the information collected by LVDT displacement sensor can be analyzed, processed and saved in real time for comparative analysis in the future.

The signals collected by LVDT displacement sensors are various, such as length, thickness, angle, deformation, temperature and distortion signals, so many kinds of LVDT displacement sensors will be used here. LVDT displacement sensor is just one of them, but it is a leader in displacement and size detection.

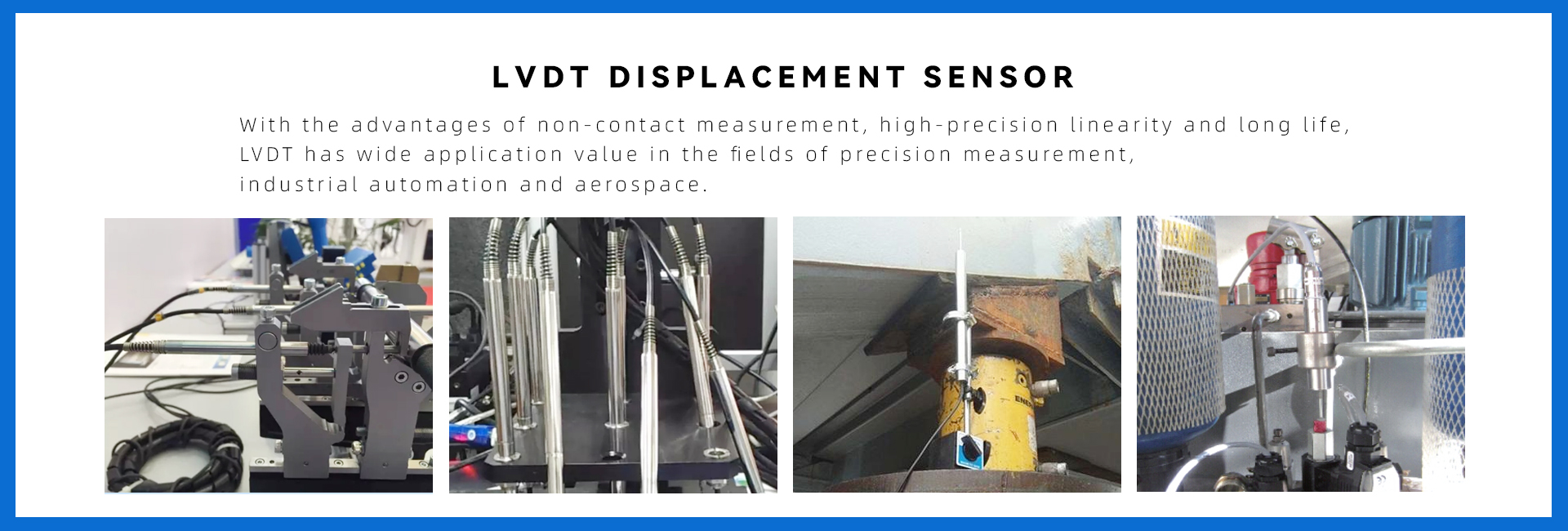

The differential transformer displacement sensor (LVDT displacement sensor) developed by SOP Group can be widely used in shaft diameter runout detection, textile machinery detection, valve position detection and control, roller gap measurement, vehicle braking device wear measurement, robot, precision displacement measurement, on-line detection of automobile parts, positioning of machine tools and tools, hydraulic cylinder positioning, bridge deck displacement detection, subway tunnel engineering protection, scientific research institutions and other national economic sectors, and can be used to measure elongation, vibration, object thickness and so on.

LVDT displacement sensor has excellent performance and is suitable for high precision and high repeatability measurement in quality control and measurement applications. The probe adopts high hardness wear-resistant silicon nitride ceramics, and the moving part of the measuring shaft adopts precision guide rail. The LVDT displacement sensor is powered by a convenient single power supply+12 ~ 30VDC, and the electronic circuit is sealed in a 304 stainless steel metal tube, which can work in harsh environments such as humidity and dust. The output signal is standard 0-5V,0-10V, 4-20mA or RS485 output which can be used by computer or PLC.