Linear displacement sensor KPZ

Linear displacement sensor KPZ

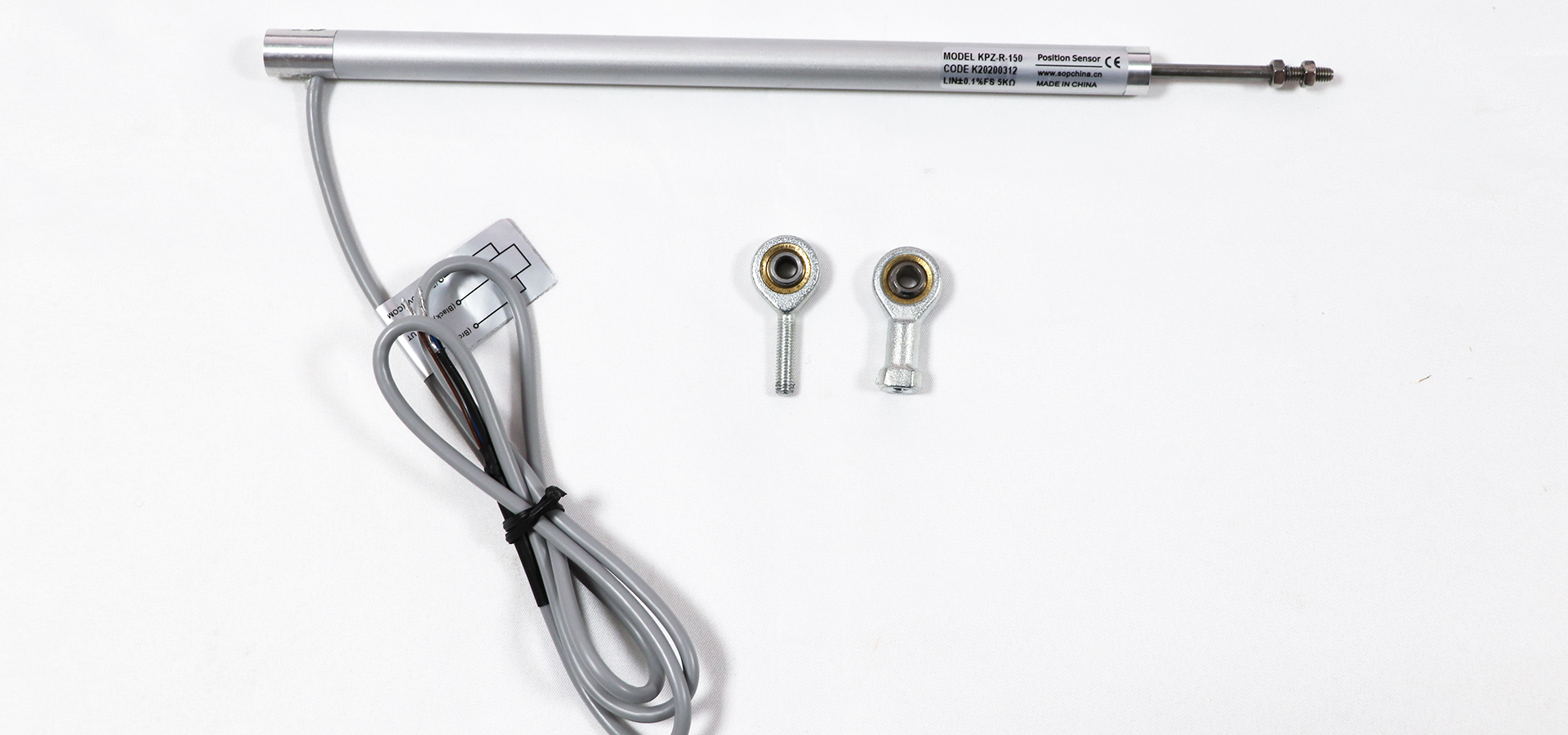

KPZ is a miniature rod-type linear displacement sensor (also known as an electronic ruler/resistance ruler), belonging to the subdivision series of potentiometer-type displacement sensors. It is suitable for use in confined spaces, with excellent linearity and easy installation. Next, let's take a look at its suitable working environment, application scenarios, selection and installation points, and application advantages.

一.The unique design of the KPZ series makes it particularly suitable for working in the following environments:

1.Space-constrained: suitable for installation in narrow mechanical gaps

2.Harsh environment: With IP65 protection, it can operate in oily, humid, and dusty environments (such as injection molding workshops and mines)

3.High-speed motion: allows a maximum speed of 5m/s, suitable for real-time monitoring of high-frequency reciprocating motion

4.Simple and straightforward: analog output (resistance/voltage/current), no need for complex signal conversion, directly interfacing with PLC/servo system

二.Application Scenario

1. Plastics and Rubber Machinery (the most mainstream application)

Injection molding machine: Monitor the opening and closing position of the mold plate and the ejection distance of the ejector pin to ensure molding accuracy

Blow molding machine: parison wall thickness control, adjusting the die gap through displacement feedback

Rubber vulcanizing machine: precise control of mold clamping position to prevent material overflow

https://www.sopsensor.com/product/kpm-linear-distance-position-sensor

https://www.sopsensor.com/product/kpm-linear-distance-position-sensor

2. Hydraulic and pneumatic systems

Hydraulic cylinder: directly installed outside or inside the cylinder, detecting the extension and retraction position of the piston rod, used in construction machinery (excavators, concrete pump truck booms)

Servo hydraulic system: valve spool displacement feedback in closed-loop control

Cylinder position: Detect the position of the cylinder piston to achieve multi-point positioning control

3. Automation and robotics

Industrial robot: detection of joint arm extension position, monitoring of gripper opening and closing degree

Automated production line: Precise positioning of assembly robotic arms (with a typical stroke range of 25-100mm)

AGV/AMR: Lifting mechanism height detection, fork positioning

4. Manufacturing of specialized equipment

Brick-making machinery: Control the position of the pressing mold to ensure consistent density of the bricks

Glass manufacturing: control of cutting blade position and mold opening and closing

Printing and packaging: adjustment of printing roller gap, positioning of paper cutter blade

Woodworking machinery: height adjustment of sliding table saw, glue quantity control of edge banding machine

5. Agriculture and special machinery

Combine harvester: digging depth control (such as monitoring the electric push rod travel of 50mm in garlic harvester)

Seeder: Real-time adjustment of ditching depth

Sanitation vehicles: Garbage compaction mechanism, dump truck lifting angle monitoring

6. Medical and laboratory equipment

Medical bed/operating table: detection of lifting height and tilt angle (low noise, smooth output characteristics)

Analytical instrument: Precise positioning of the sample stage (utilizing its infinite resolution characteristic)

Rehabilitation equipment: Monitoring of joint range of motion for rehabilitation robots

三. Key points of selection and installation

| Application scenario | Recommended range | Key configuration | Matters need attention |

| Small injection molding machine thimble | 25-50mm | Ball joint installation | high-temperature resistance |

| External hydraulic cylinder | 100-300mm | Flange installation | Dust-proof and waterproof IP67 |

| Robot joint | 10-50mm | Cable outgoing+bracket installation | High repeatability ±0.01mm |

| Vibration environment | Arbitrarily | Shock absorber bracket +4-20mA output | 40g anti-vibration |

四. Leveraging Advantages

Compared to other types of displacement sensors, the KPZ series is irreplaceable in the following scenarios:

1. Cost-sensitive automation: The price is 1/3 to 1/5 of that of magnetostrictive sensors, making it suitable for large-scale OEM (Original Equipment Manufacturing) supporting

2. In situations where the installation space is less than 20mm: such as small pneumatic fixtures, micro hydraulic stations

3. Direct analog input: No A/D conversion module is required, and it can be directly connected to a frequency converter or a microcontroller

4. High-endurance reciprocating motion: Conductive plastic resistor + multi-contact brush design, with an endurance of up to 30 million to 100 million cycles

Typical case: In a certain garlic combine harvester, the KPZ-50mm sensor is mounted on an electric push rod to monitor the lifting and lowering displacement of the digging shovel in real time (within the range of 0-50mm, with a 0-5V output). It cooperates with machine vision to achieve a digging depth control accuracy of ±5mm