What should be paid attention to when purchasing load cell products?

What should be paid attention to when purchasing load cell products?

In scenarios such as industrial automation, logistics warehousing, and food processing, weighing sensors serve as core metrological components, and their quality directly impacts the stability of equipment operation and the accuracy of data. However, the market is filled with a wide range of products, with inferior sensors often attracting buyers with low prices but suffering from material defects and rough craftsmanship, leading to reduced accuracy, shortened lifespan, and even safety accidents. Next, we will systematically analyze the pitfalls to be wary of when purchasing, covering dimensions such as technical principles, material craftsmanship, and performance parameters, to assist you in establishing a scientific selection logic.

1. Core Performance Parameters: Accuracy and Stability are the Core Functions of Lifeline Weighing Sensors.

These sensors convert mass signals into measurable electrical signals, and their accuracy directly determines the reliability of the system. Inferior products often reduce costs by falsely marking the range and simplifying the calibration process, leading to the following issues:

Nonlinear Error: High-quality sensors exhibit a strict linear relationship between output signal and load, whereas inferior products produce significant curve fluctuations due to uneven elastomer materials or deviation in strain gauge attachment.

Hysteresis: When repeatedly loading the same weight, inferior sensors, due to their loose internal structure, exhibit significant differences in output values, affecting the accuracy of dynamic weighing scenarios.

Temperature drift: When the ambient temperature changes, inferior sensors may experience zero-point drift or sensitivity variations due to mismatched material thermal expansion coefficients, necessitating frequent recalibration.

Avoidance advice: Require suppliers to provide a full-range linearity test report, and give priority to sensors that adopt laser welding sealing and stainless steel integrated molding. Such structures can effectively reduce environmental interference.

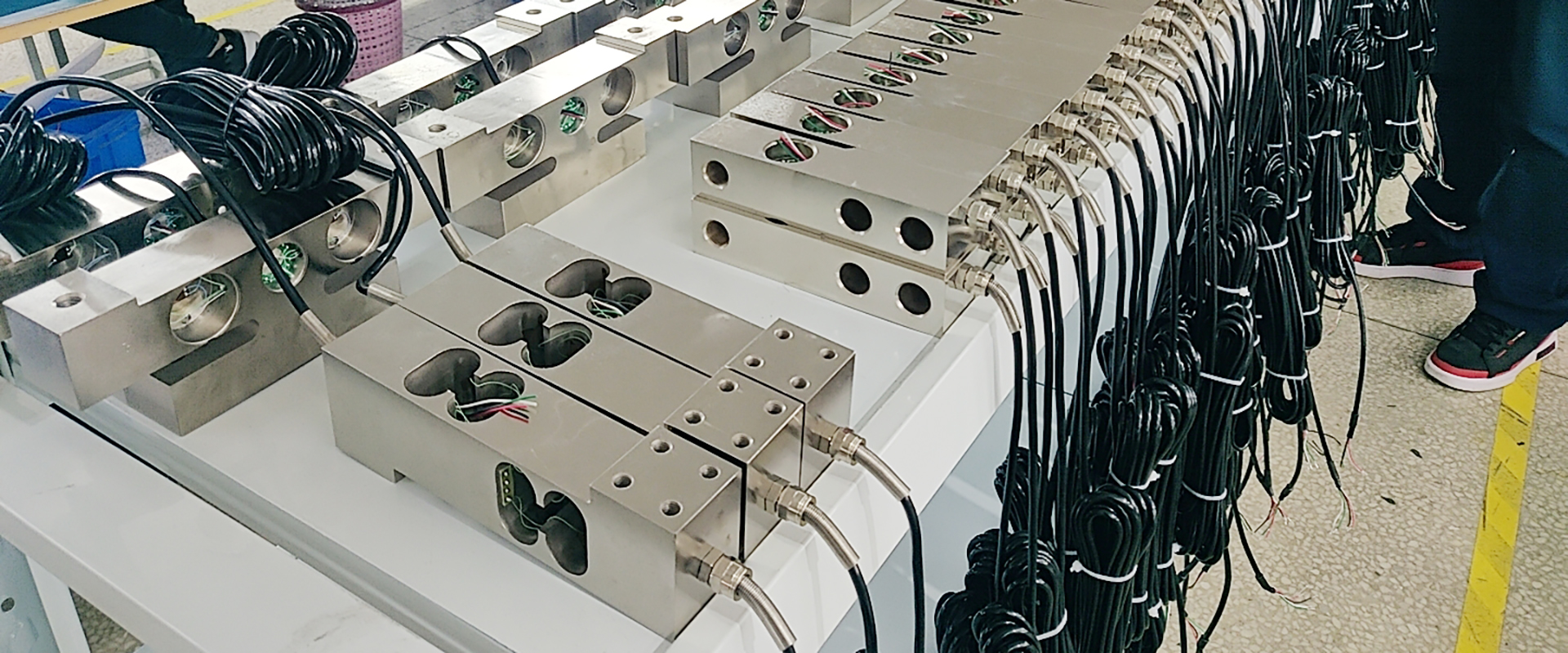

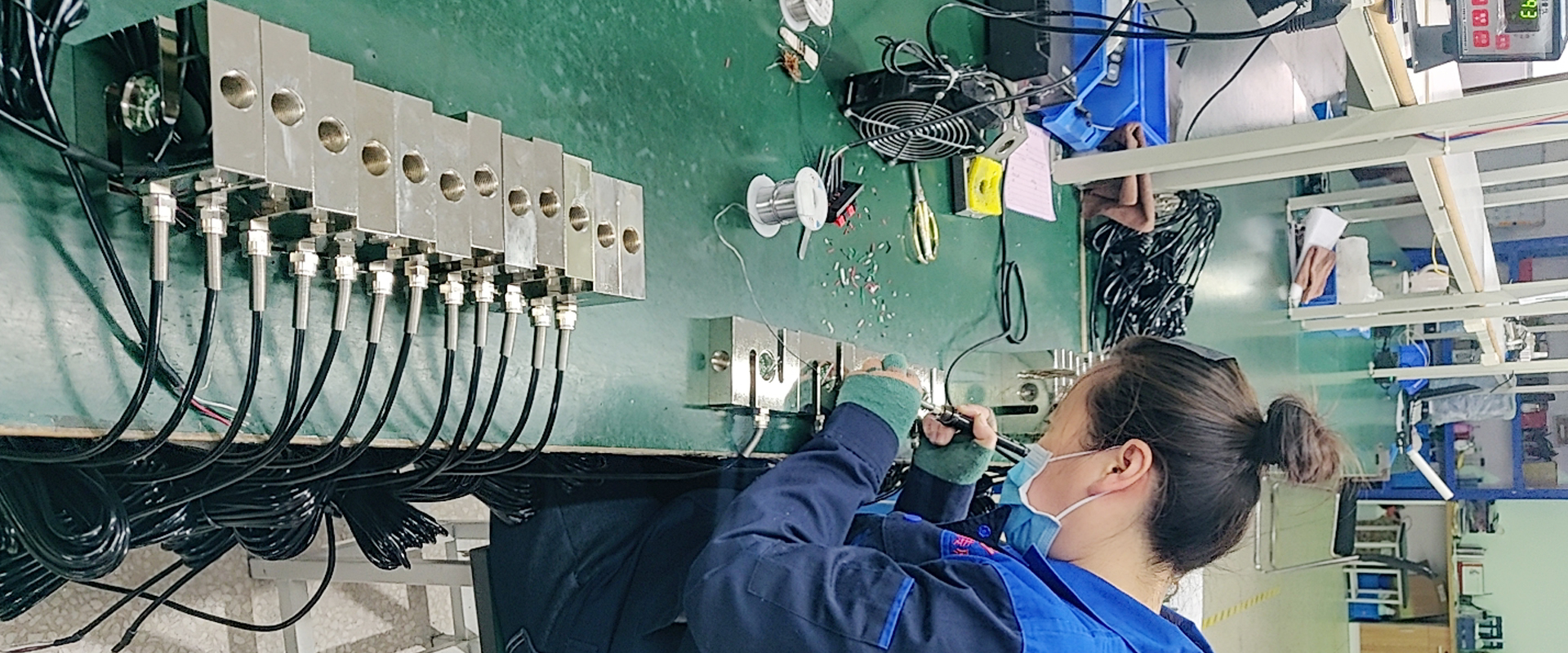

2. Materials and Processes: Key Factors Affecting Service Life.

Sensors are subjected to alternating loads over a long period, and material fatigue and seal failure are the primary modes of failure. Poor-quality products often cut corners in the following aspects:

Elastomer Materials: High-quality sensors use aviation-grade aluminum alloy or alloy steel, which undergoes special heat treatment to enhance fatigue resistance; inferior products use ordinary steel, which is prone to plastic deformation after repeated stress.

Strain gauge technology: High-end products utilize metal foil strain gauges, achieving micro-strain detection through silicon diffusion technology; low-end products employ thick-diameter resistance wires, which have low sensitivity and are prone to oxidation and fracture.

Sealing structure: High-quality sensors employ laser welding or vacuum helium testing processes, achieving a protection level of IP68; inferior products merely use glue for filling, leading to circuit shorting after moisture intrusion.

Avoidance advice: Observe the surface treatment process of the sensor. High-quality products usually have an anodized or nickel-plated layer; tap the elastomer gently and listen to the sound. High-quality products should emit a crisp metallic sound, while inferior products will emit a dull echo due to internal voids.

3. Environmental adaptability: Don't let scenarios become "killers" Different application scenarios have differentiated requirements for sensors, and blind procurement may lead to equipment malfunctioning:

Corrosive environment: Chemical and aquatic product processing scenarios require the selection of 316L stainless steel material, while inferior products using 304 stainless steel will quickly rust.

Electromagnetic interference: Equipment close to motors and frequency converters should use signal cables with shielding layers. Poor-quality sensors often omit this design, leading to data fluctuations.

Mechanical shock: Sensors with strong overload resistance should be selected for logistics sorting and mining scenarios. Inferior products have falsely high nominal overload values, and they are permanently damaged after actually withstanding shocks.

Avoidance advice: Clarify the temperature and humidity range, vibration frequency, and chemical substance exposure conditions of the usage scenario, and require suppliers to provide environmental adaptability test reports.

Q1: How can we quickly determine if a sensor is overloaded and damaged?

A: Observe whether the elastomer exhibits permanent deformation, and use a multimeter to check if the output signal returns to zero. Poor-quality sensors often suffer from strain gauge fracture or circuit burnout due to overload.

Q2: What could be the possible reasons for unstable sensor signals?

A: It may be caused by poor cable contact, water ingress due to seal failure, electromagnetic interference, or uneven installation base. It is necessary to investigate the connector, protection level, and grounding condition one by one.

Q3: Why do sensors from the same batch exhibit differences in accuracy?

A: High-quality products undergo temperature compensation and linear calibration before leaving the factory, while inferior products, due to omission of this process or insufficient accuracy of calibration equipment, exhibit significant individual performance variations.

Q4: How long does a sensor typically last? How can its lifespan be extended?

A: High-quality products can last for millions of cycles. To extend their lifespan, it is important to avoid overuse, clean regularly to prevent corrosion, and choose a protection level that matches the specific usage scenario.

Q5: Do I need to recalibrate the entire system after replacing the sensor?