How to choose a load cell? Recommendations for suitable models for different weighing scenarios

How to choose a load cell? Recommendations for suitable models for different weighing scenarios

一、Core of model selection: Clarify requirements and pinpoint key indicators

1. Measurement range and scale design

The sensor range should cover the maximum weight of the object being measured, with a safety margin reserved. For example, when weighing industrial material tanks, the impact load of the material needs to be considered, and the range is usually 1.2-1.5 times the maximum load capacity. If the range is too small, overload may cause permanent deformation of the elastic body; if the range is too large, the resolution will decrease, affecting the accuracy of small weight measurements.

2. Precision and error control

The accuracy level is determined comprehensively by indicators such as nonlinearity, hysteresis, and repeatability. Industrial weighing scenarios (such as truck scales) typically require an accuracy of 0.1%-0.5%, while precision metrology (such as laboratory balances) requires an accuracy of 0.01% or even higher. It should be noted that higher accuracy is not necessarily better, and excessively pursuing high accuracy can significantly increase costs.

3. Environmental adaptability design

Temperature impact: High-temperature environments may cause the strain gauge to age, necessitating the selection of high-temperature-resistant sensors or the addition of thermal insulation devices;

Corrosion protection: In chemical scenarios, stainless steel materials or surface coating treatments are required to prevent erosion from the medium;

Sealing level: For humid environments, a protection level of IP67 or higher should be selected to prevent moisture intrusion and subsequent short circuits.

二、Scenario-based matching: structure type and installation method

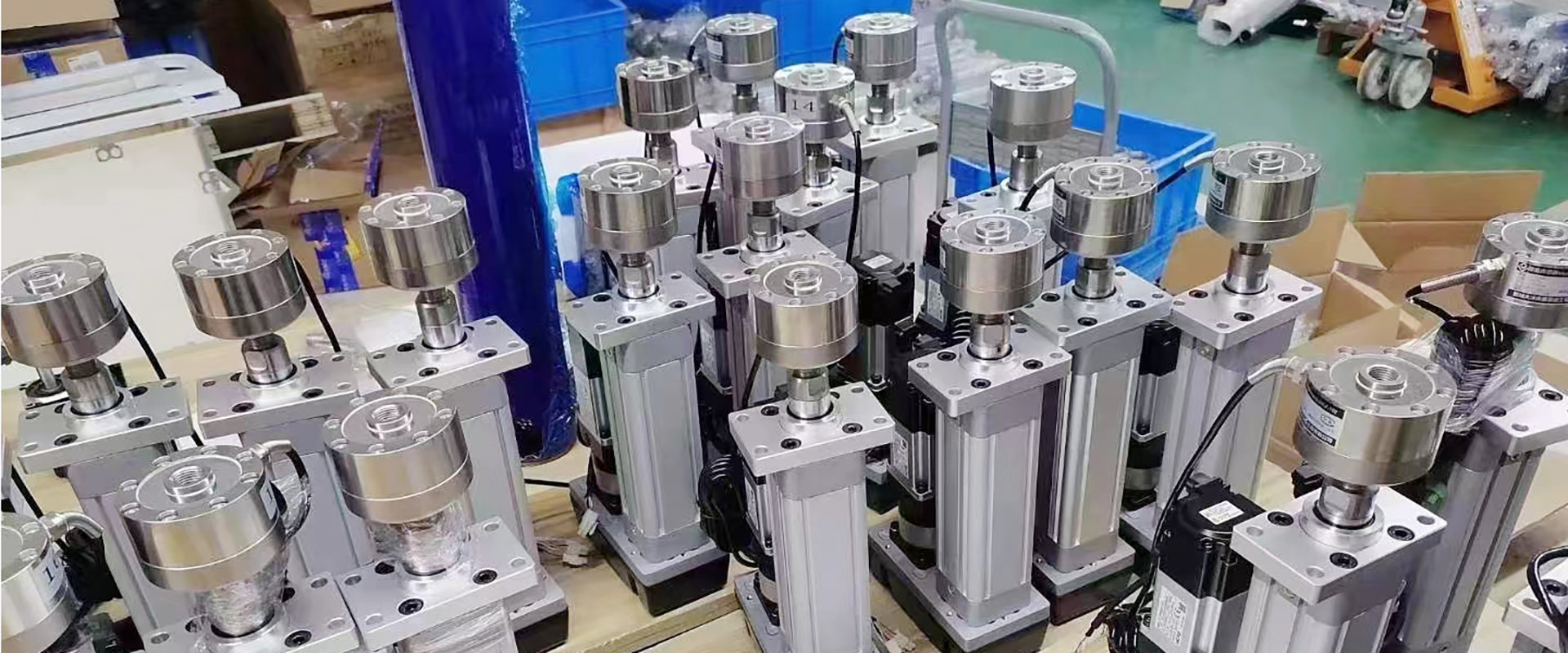

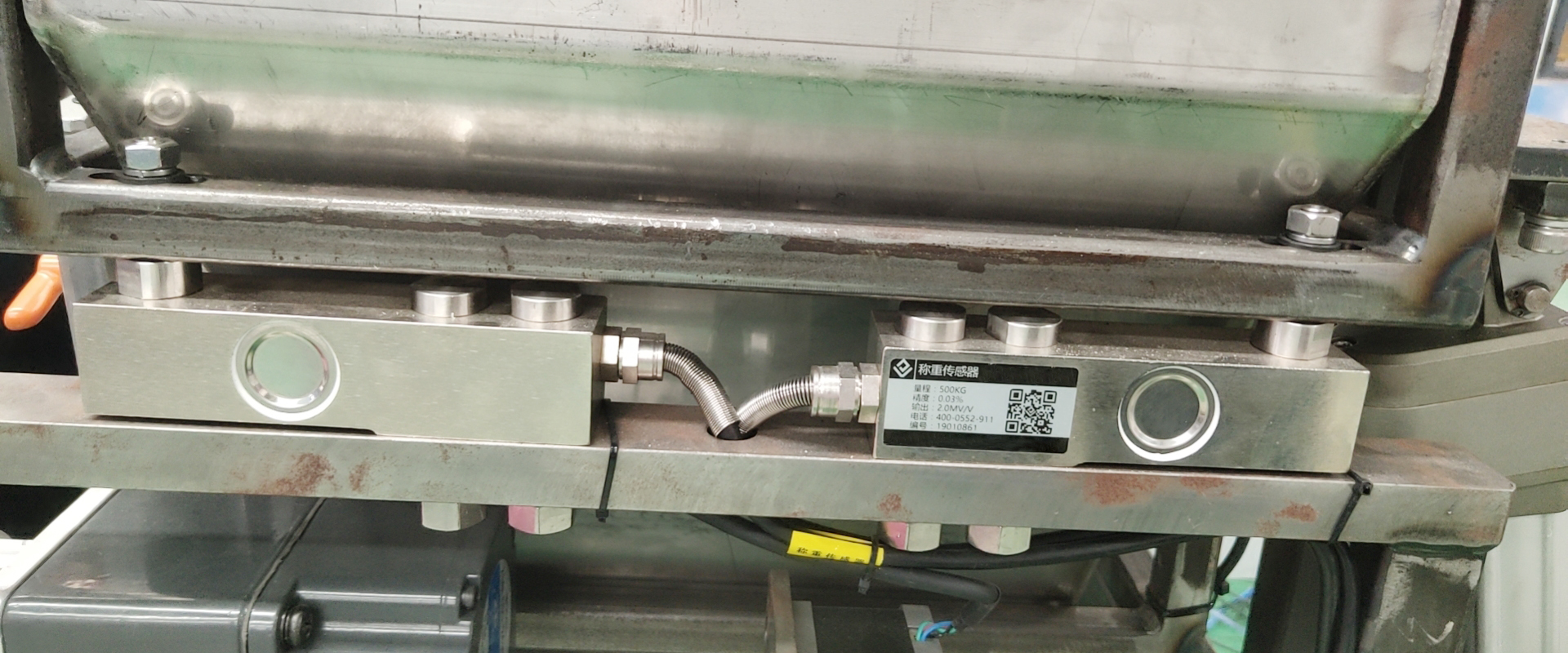

1. Industrial weighing: bridge sensor

Applicable scenarios: truck scales, track scales, large material tanks

Structural characteristics: Double shear beam design, strong resistance to eccentric loading, capable of withstanding combined loads in both vertical and horizontal directions.

Installation points: Horizontal alignment is required to avoid measurement errors caused by lateral forces; when multiple sensors are connected in parallel, the output consistency needs to be adjusted through a junction box.

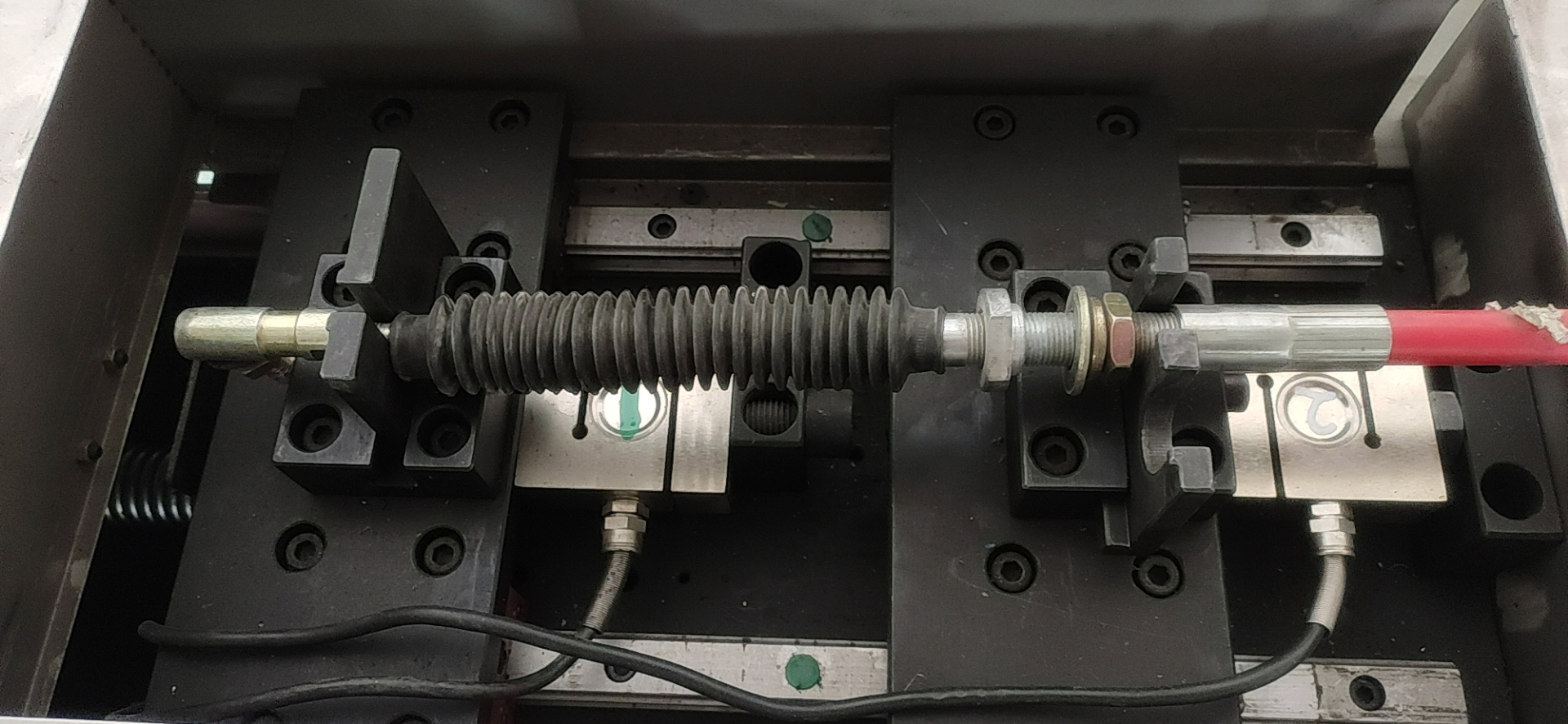

2. Dynamic monitoring: cantilever beam sensor

Applicable scenarios: monorail crane, conveyor belt weighing, and vibrating screen metering

Structural characteristics: Cantilever shear structure, fast response speed, suitable for high-frequency dynamic load monitoring.

Anti-interference design: A limiting device is required to eliminate horizontal impact forces; digital interfaces (such as RS485) are used for signal output to reduce noise from analog signal transmission.

3. Precision Metrology: S-type Tension-Compression Sensor

Applicable scenarios: feed ingredient mixing, laboratory force testing, medical equipment

Structural characteristics: S-shaped elastomer, bidirectional measurement in tension and compression, excellent linearity.

Accuracy optimization: Adopting a four-wire system for wiring to eliminate the impact of wire resistance; equipping with high-resolution instruments to achieve microgram-level measurement.

三、Signal output and system compatibility

1. Analog signal vs digital signal

Analog signal (4-20mA/0-10V): suitable for traditional control systems, but susceptible to electromagnetic interference, requiring shortening of transmission distance or adding a shielding layer;

Digital signal (RS485/CAN): strong anti-interference capability, supports multi-sensor networking, suitable for distributed weighing systems.

2. Impedance matching and controller compatibility

The sensor output impedance needs to match the controller input impedance. For example, some microcontrollers require the sensor impedance to be below 10kΩ; otherwise, a signal conditioning module needs to be added.

The selection of load cells should be guided by scenario requirements, focusing on core indicators such as measurement range, accuracy, and environmental adaptability. By considering structural characteristics such as bridge, cantilever beam, and S-shaped designs, a balance between performance and cost can be achieved. The measurement stability can be further enhanced through the design of signal output methods and system compatibility. During the selection process, it is necessary to avoid "over-design" or "low-end compromise", and to base decisions on long-term operational benefits.

Q1: How to determine if a sensor is overloaded?

A: Overloading can lead to abnormal output signals (such as full-scale overflow), deformation of the elastic body, or zero drift. When selecting a model, ensure that the measurement range covers the maximum expected load and includes a safety margin.

Q2: What should I do if the sensor response is slow in dynamic scenarios?

A: Choose cantilever beam or shear beam sensors, optimize signal output frequency, reduce mechanical structure gaps, and minimize impact force interference.

Q3: How to choose sensors for humid environments?

A: Preferably choose products with a protection level of IP67 or above, utilizing welding sealing or vacuum pumping and nitrogen filling processes; avoid using glue sealing to prevent sealing failure due to long-term moisture exposure.

Q4: How to ensure consistent accuracy when multiple sensors are connected in parallel?

A: Adjust the zero point and gain through the junction box, using sensors from the same batch; perform regular calibration to compensate for output differences caused by temperature changes.

Q5: Is higher sensor accuracy always better?

A: Accuracy needs to align with system requirements. High-precision sensors come with high costs and have stricter requirements for the environment and installation. Pursuing excessive precision may lead to resource waste.