Load Cell Selection Manual: Classification by Structure Type and Application Scenario

Load Cell Selection Manual: Classification by Structure Type and Application Scenario

In industrial production, logistics warehousing, scientific research, and other scenarios, the accuracy of weighing data directly affects production efficiency and product quality. However, many people often encounter issues such as large measurement errors and shortened equipment lifespan when selecting load cells, due to a lack of understanding of structural type differences and mismatch with application scenarios. This article will provide you with a systematic selection method from two aspects: structural type classification and application scenario adaptation, helping you avoid common selection pitfalls.

一、Common pain points in weighing sensor selection

In the actual selection process, users often face two core issues. First, there is a lack of clarity in understanding structural types, such as confusing the applicable scenarios of S-type and cantilever beam sensors, and using S-type sensors suitable for tensile force measurement for material tank weighing, resulting in decreased measurement accuracy. Second, the special requirements of the application scenario are often overlooked, such as selecting ordinary sensors in high-temperature environments, which can affect data accuracy due to temperature drift; and neglecting the protection level in humid environments, leading to moisture damage to the sensor. These issues ultimately result in frequent equipment failures and increased operational and maintenance costs for enterprises.

二、Structure Types and Characteristics of Load Cells

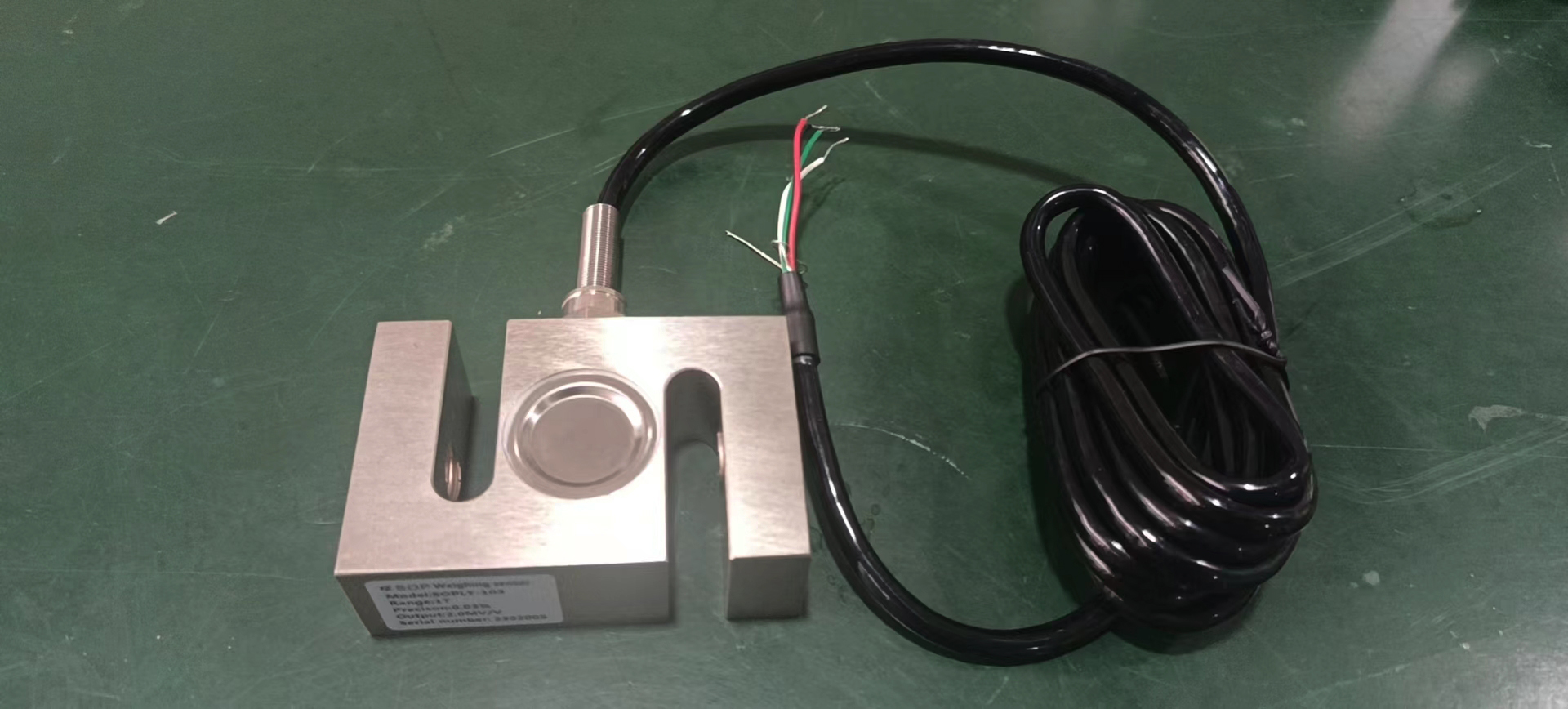

1. S-type load cell: The structure of the S-type load cell is shaped like an "S", capable of withstanding both tensile and compressive forces, with a measurement range typically ranging from 50N to 50kN. It is characterized by high accuracy (typically 0.02%-0.05% FS) and easy installation, suitable for scenarios where installation space is not critical. However, its resistance to lateral forces is relatively weak, and accuracy tends to fluctuate when affected by lateral forces.

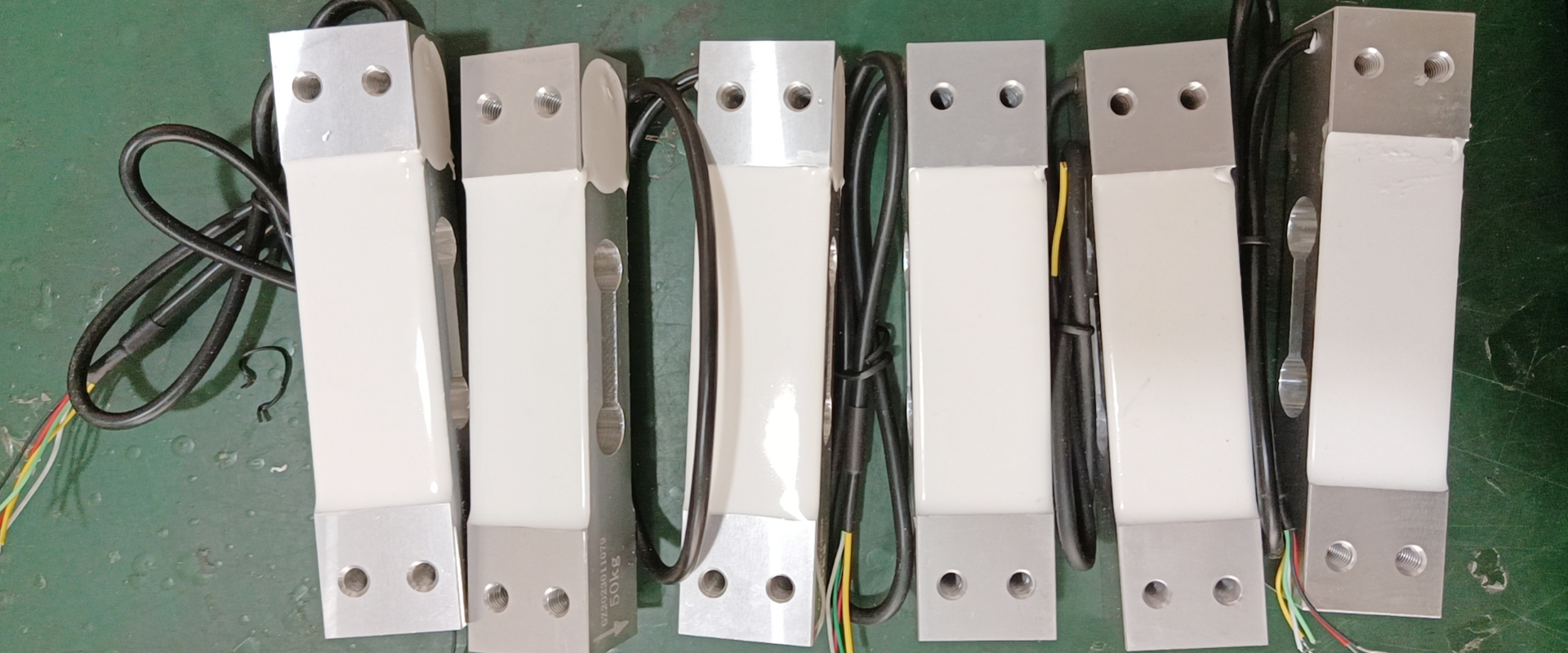

2. The cantilever beam load cell adopts a cantilever beam structure design, with a measurement range mostly between 100kg and 10t, primarily bearing pressure. Its advantage lies in its strong ability to resist eccentric loading, effectively handling situations where materials are loaded eccentrically. Additionally, its compact structure makes it suitable for installation under platform scales and hoppers, but it requires a high level of flatness of the installation surface, as unevenness can affect measurement accuracy.

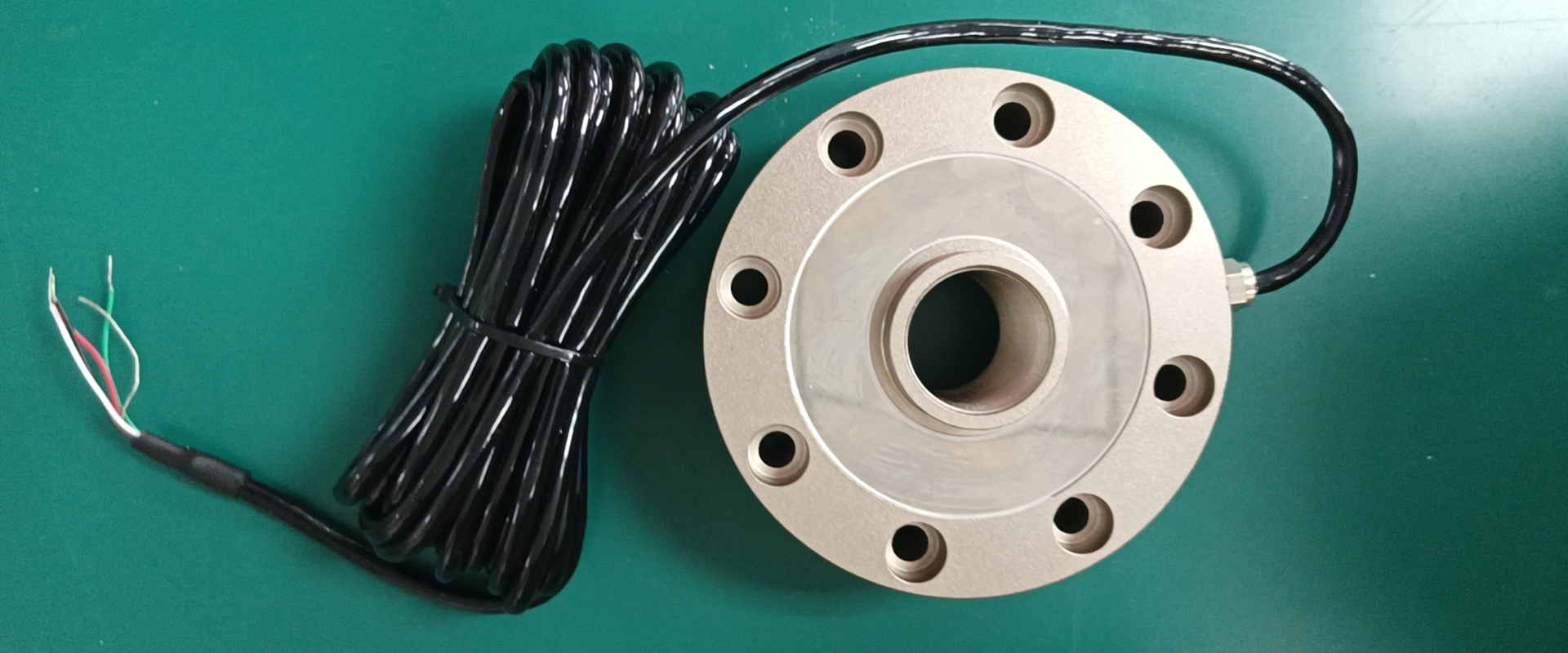

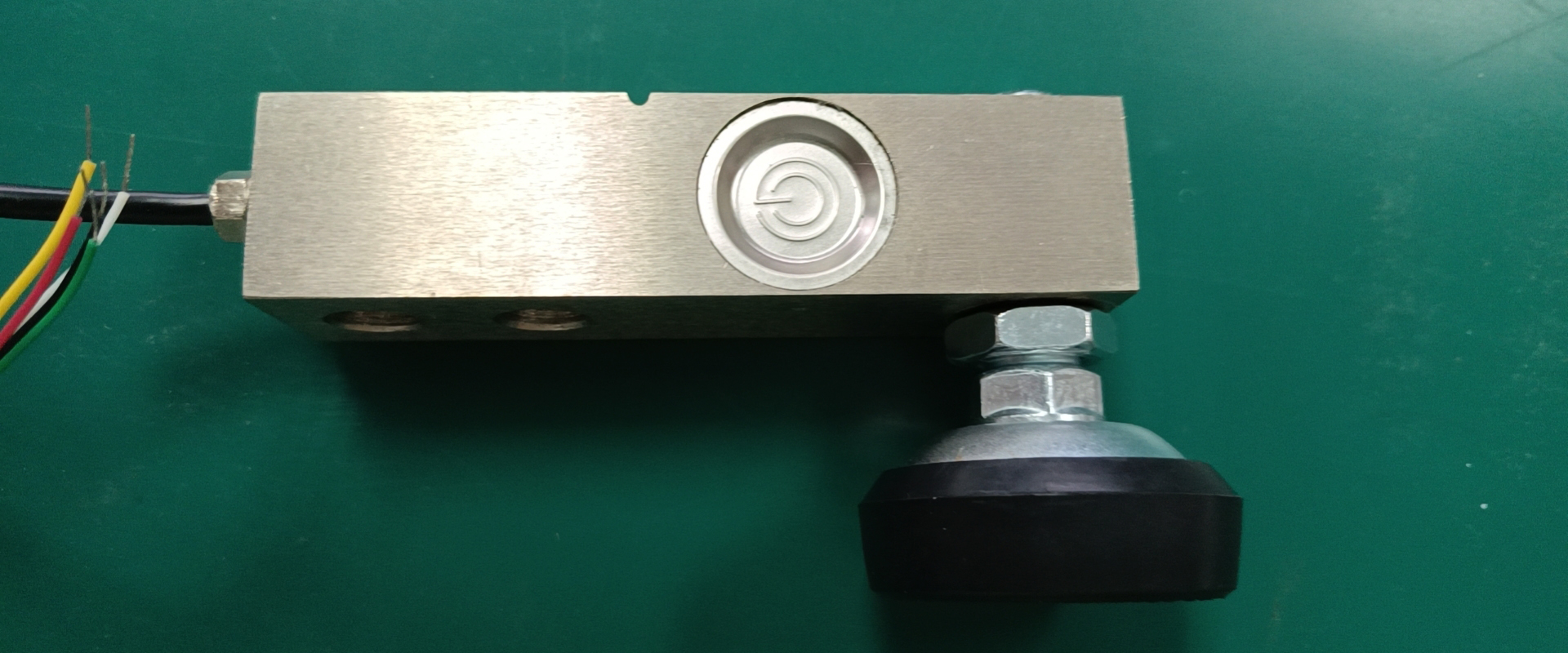

3. The column-type load cell is cylindrical in shape, with a wide measurement range (1t-100t), strong pressure-bearing capacity, excellent impact resistance and overload resistance, and a protection level that can usually reach IP67-IP68, making it suitable for harsh environments. However, it has a relatively large size, requiring a large space for installation, and strict requirements for installation coaxiality. Eccentric loading can significantly reduce accuracy.

三、Selection Plan Based on Application Scenario

1. Material Tank and Hopper Weighing Scenario In this scenario, the material is prone to eccentric loading and requires long-term stable measurement. It is recommended to use cantilever beam or column sensors. If the measurement range is within 10t and the installation space is limited, the cantilever beam type is preferred; if the measurement range exceeds 10t and the environment is harsh (such as high dust content, humidity), then choose a column sensor, ensuring that the protection level is not lower than IP67.

2. Belt conveyor weighing scenario This scenario requires real-time dynamic weighing and is subject to issues such as vibration and material impact. It is recommended to use S-type or dedicated belt scale sensors. The S-type sensor is suitable for belt conveyors with small to medium ranges (up to 50kN). If the range is larger, a columnar sensor with strong shock resistance can be selected, and a vibration reduction device should be used to minimize the impact of vibration on accuracy.

3. In tension measurement scenarios such as rope tension measurement and elevator counterweight detection, S-type load cells are the preferred choice. This is because they can accurately measure tension, and their measurement range can meet most tension measurement needs. When installing, it is necessary to ensure that the sensor axis is aligned with the direction of the applied force to avoid lateral force interference.

4. For high/low temperature special scenarios, sensors with temperature compensation function should be selected when the temperature is higher than 80℃ or lower than -20℃. Regardless of the structural type, it is necessary to confirm whether the operating temperature range of the sensor matches the actual environment, and pay attention to the temperature drift coefficient (generally required to be ≤0.002% FS/℃) to ensure measurement accuracy under extreme temperatures.

四、Common problems in weighing sensor selection

Q: Which structure of weighing sensor should be selected in a wet aquatic product processing workshop?

A: It is recommended to choose a column-type load cell, which typically has a protection level of IP68, effectively resisting water and moisture. At the same time, it is necessary to confirm that the operating temperature range of the load cell is suitable for the workshop environment, to avoid damage or accuracy degradation due to moisture.

Q: Which sensor is suitable for measuring the tensile force of small parts with a measuring range of around 1kN?

A: The S-type load cell is preferred, as it has a measurement range covering 1kN, can accurately measure tensile force, is easy to install, and is suitable for tensile testing scenarios involving small parts.

Q: When weighing materials on a platform scale, they are often placed eccentrically. How should the scale be selected?

A: Choose a cantilever beam load cell, which has strong resistance to eccentric loading and can handle situations where materials are loaded eccentrically. Ensure the platform is flat during installation to further enhance measurement accuracy.

Q: What should be paid attention to when weighing the material tank next to the high-temperature kiln with a sensor?

A: A sensor with temperature compensation function should be selected. In terms of structure, the cantilever beam type (for small measurement ranges) or column type (for large measurement ranges) can be chosen based on the measurement range. At the same time, it is necessary to confirm that the upper operating temperature limit of the sensor is higher than the actual temperature next to the kiln, to avoid temperature drift affecting the data.