Selection, Working Principle, and Application of Tension Sensors

Selection, Working Principle, and Application of Tension Sensors

The tension sensor is suitable for dynamic measurement and static measurement. A strain gauge made of a metal wire machine or a metal cat strain gauge is attached to the back of the load surface. When the load surface is stressed, the strain gauge will deform and its electrical parameters will change accordingly. Tension sensor has a very important application in many fields of people's daily life, so we must pay attention to ensure that the tension sensor can work normally during the application. Let's understand the selection principle and application of tension sensor together:

Selection principle of tension sensor:

1. Type of tension sensor

For example, the size of the measuring range, the volume requirement of the measured position, whether the measuring method is contact or non-contact, the signal derivation method, wired or non-contact measurement, domestic or oral, or development according to special circumstances. After determining which type of tension sensor to choose, consider its specific performance indicators.

2. Sensitivity of tension sensor

Generally, in the linear range of tension sensor, the higher the sensitivity, the better. Because only when the sensitivity is high, the value of the output signal corresponding to the measured change is relatively large, which is beneficial to signal processing. Working principle of tension sensor According to its working principle, it can be divided into strain gauge type and micro-displacement type.

The strain gauge type is that the tensile strain gauge and the compressive strain gauge are connected together in a bridge way. When subjected to external pressure, the electrical value of the strain gauge also changes, and the change value will be directly proportional to the tensile force. The micro-displacement type is called the micro-displacement type tension detector because the displacement of the leaf spring is extremely small, about 200 microns. In addition, from the external structure, it can be divided into: shaft table, shaft-through, cantilever and so on.

Application of tension sensor:

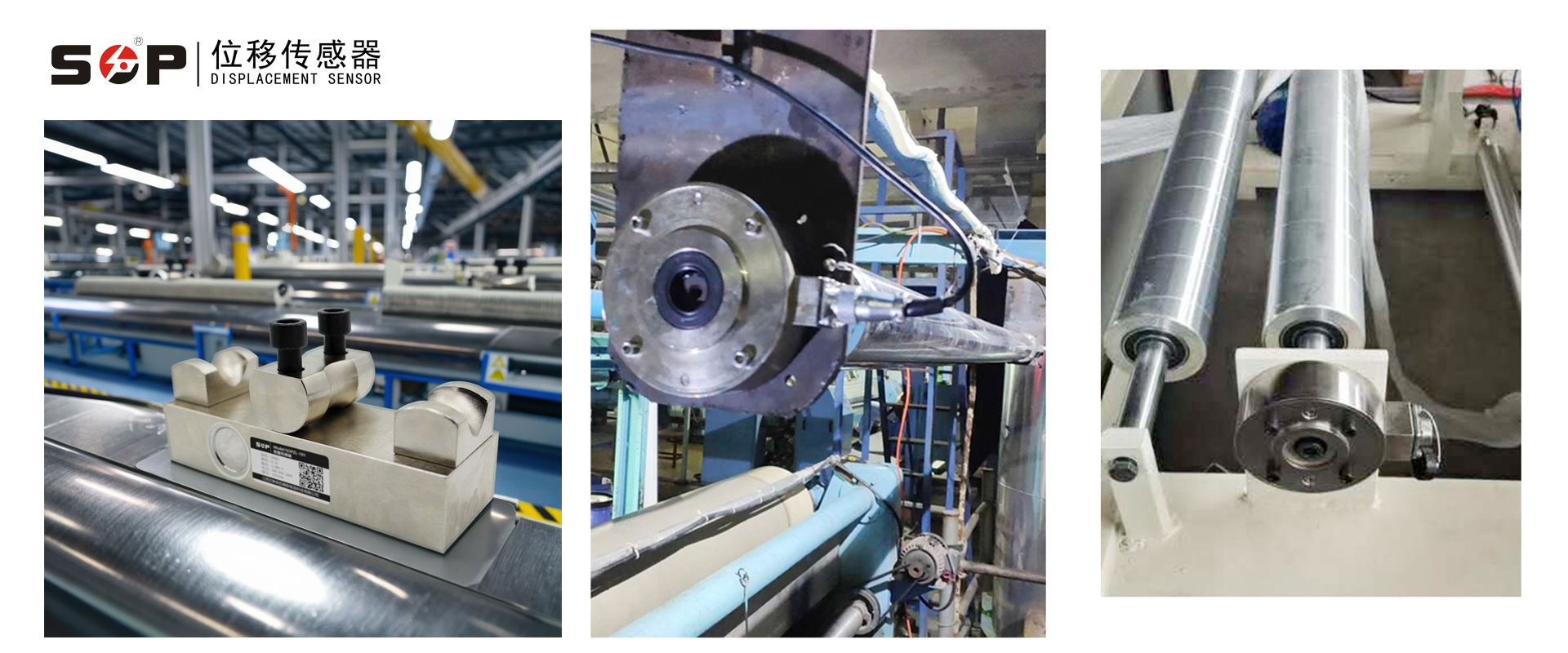

Tension sensor, that is, tension detector, is usually used with automatic tension controller, magnetic powder clutch and magnetic powder brake. It can accurately detect the bending degree of steel plate spring under load, so as to detect the tension. The tension sensor has the characteristics of high stability, good linearity, fast response, light weight and small volume. It is an ideal test equipment for tension control in printing, packaging, film printing and processing.

Jiangxi SOP Precision Intelligent Manufacturing Technology Co., Ltd. specializes in developing and producing high-quality and high-precision force sensors, mainly including linear displacement sensors, LVDT displacement sensors, magnetostrictive displacement sensors, cantilever-type weighing sensors, S-type weighing sensors, spoke-type weighing sensors, tension sensors, column-type weighing sensors, ring-type weighing sensors, micro-sensors, diaphragm-type sensors, torque sensors, pressure sensors, proximity sensors, ultrasonic flowmeters and other products.

Our products are widely used in industrial automation production lines, 3C, new energy, robotics, machinery manufacturing, medical care, textiles, automobiles, metallurgy and transportation.