Application of pressure sensor

Application of pressure sensor

Five application fields of pressure sensor:

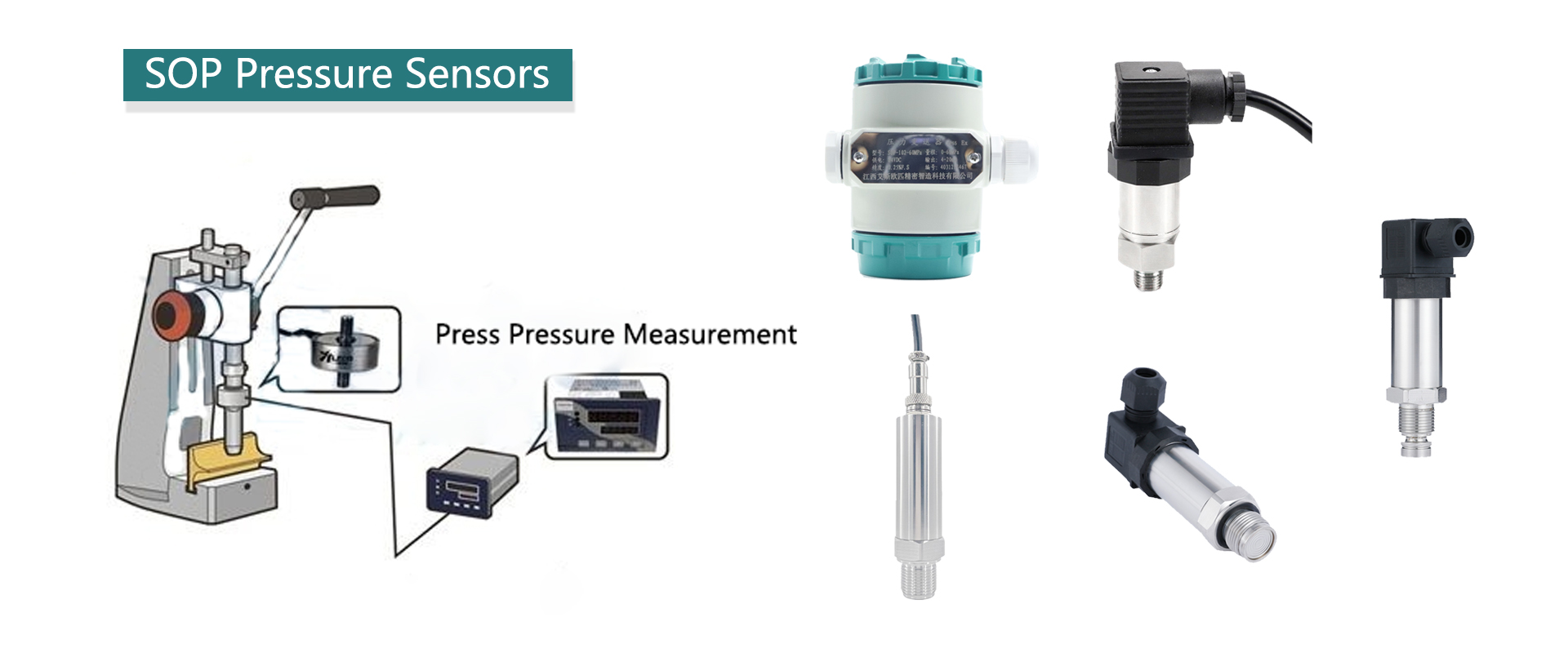

Pressure sensors are mainly used in: booster cylinder, supercharger, gas-liquid booster cylinder, gas-liquid supercharger, press, compressor, air conditioning and refrigeration equipment and other fields.

1. The pressure sensor is applied to the hydraulic system.

The pressure sensor is mainly used to complete the closed-loop control of force in the hydraulic system. When the reading core is controlled to move suddenly, several peak pressures depending on the working pressure of the system will be formed in a very short time. In the typical mobile machinery and industrial wave pressure, if such extreme working conditions are not taken into account in the design, any pressure transmitter and sensor will be destroyed soon, so it is necessary to use an impact-resistant pressure sensor. There are two main methods to realize the impact resistance of the pressure sensor, one is to change the strain-gauge chip, and the other is to connect the disk tube. Generally, the first method is adopted in the hydraulic system, mainly because it is convenient to install, and another reason is that the pressure sensor has to bear the uninterrupted pressure pulsation from the hydraulic pump.

2. The pressure sensor is applied to the safety control system.

Pressure sensors are often used in safety control systems, mainly for the safety management system of air compressors. There are many sensor applications in the field of safety control. As a very common sensor, it is not surprising that pressure sensors are used in safety control systems. Generally, the application in the field of safety control is considered from the aspects of performance, price and safety and convenience of actual operation. It has been proved that the effect of selecting Leroy sensor is very good. Leroy sensor uses the processing technology of mechanical equipment to install some components and signal regulators on a small piece of Soviet film, so its small size is also one of its advantages. Besides, its low price is another great advantage, which can improve the system test to a certain extent? Accuracy, in the safety control system, the pressure brought by the compressor is controlled to a certain extent by installing a pressure sensor in the pipeline equipment at the air outlet, which is a certain protective measure and a very effective control system. When the compressor is started normally, if the pressure value does not reach the upper eye, the controller will open the air inlet and adjust it to make the equipment reach the maximum power.

3. The pressure sensor is applied to the injection mold.

Pressure sensor plays an important role in injection mold. The pressure sensor can be installed in the nozzle, hot runner system, cold runner system and mold cavity of the injection molding machine, and it can measure the plastic pressure somewhere between the nozzle and the mold cavity of the injection molding machine during injection, filling, pressure maintaining and cooling.

4. The pressure sensor is used to monitor the mine pressure.

As one of the key technologies of mine pressure monitoring. On the one hand, we should correctly use all kinds of existing sensors to serve the mining industry. On the other hand, as sensor manufacturers, we need to develop new pressure sensors to adapt to more mining industry applications. There are many kinds of pressure sensors, and based on the special environment of mine pressure monitoring, mine pressure sensors mainly include vibrating wire pressure sensor, semiconductor piezoresistive pressure sensor, metal strain gauge pressure sensor, differential transformer pressure sensor and so on. These sensors are widely used in the mining industry, and which sensor to use depends on the specific mining environment.