What is a centrifugal fan?

What is a centrifugal fan?

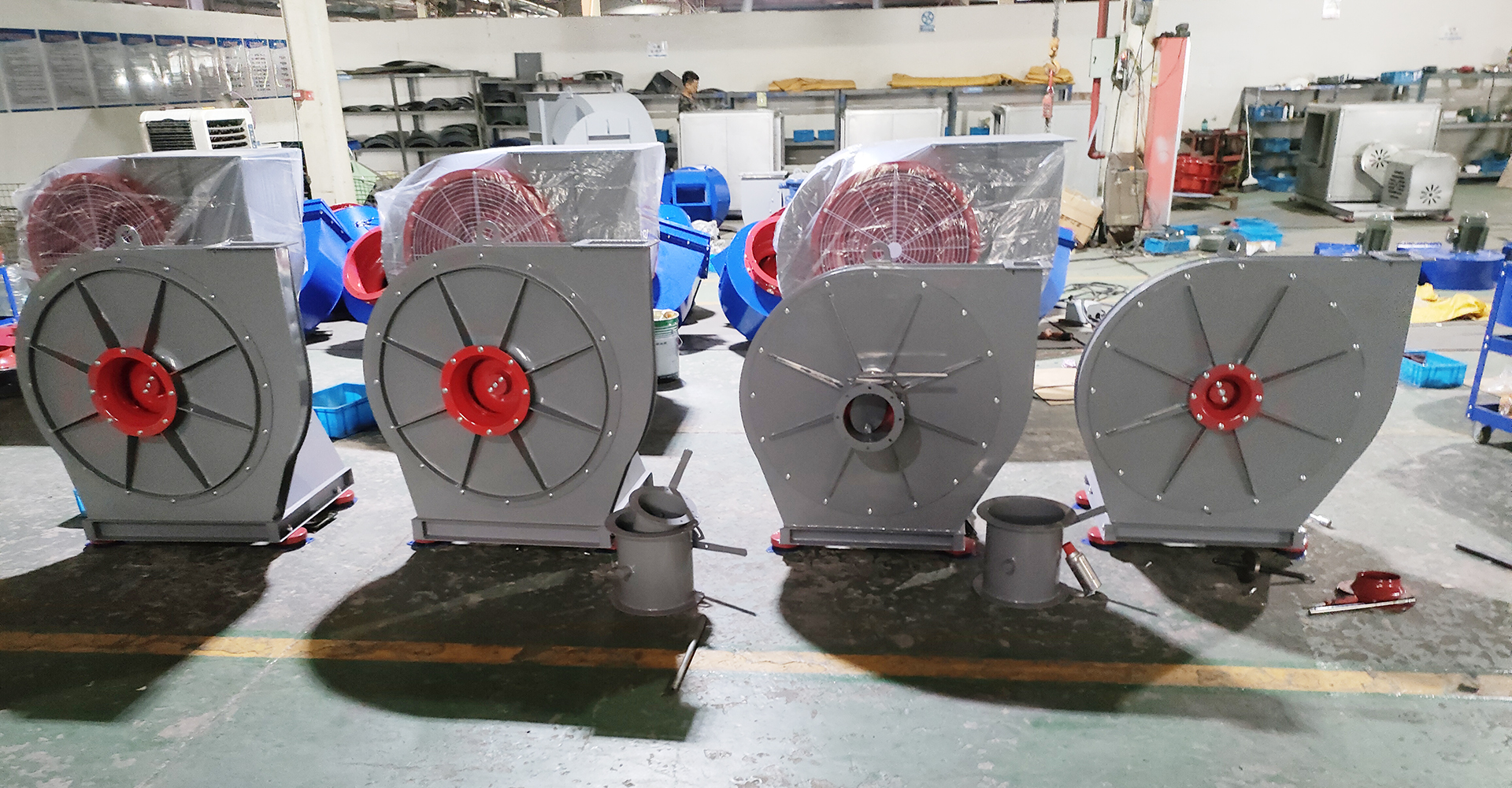

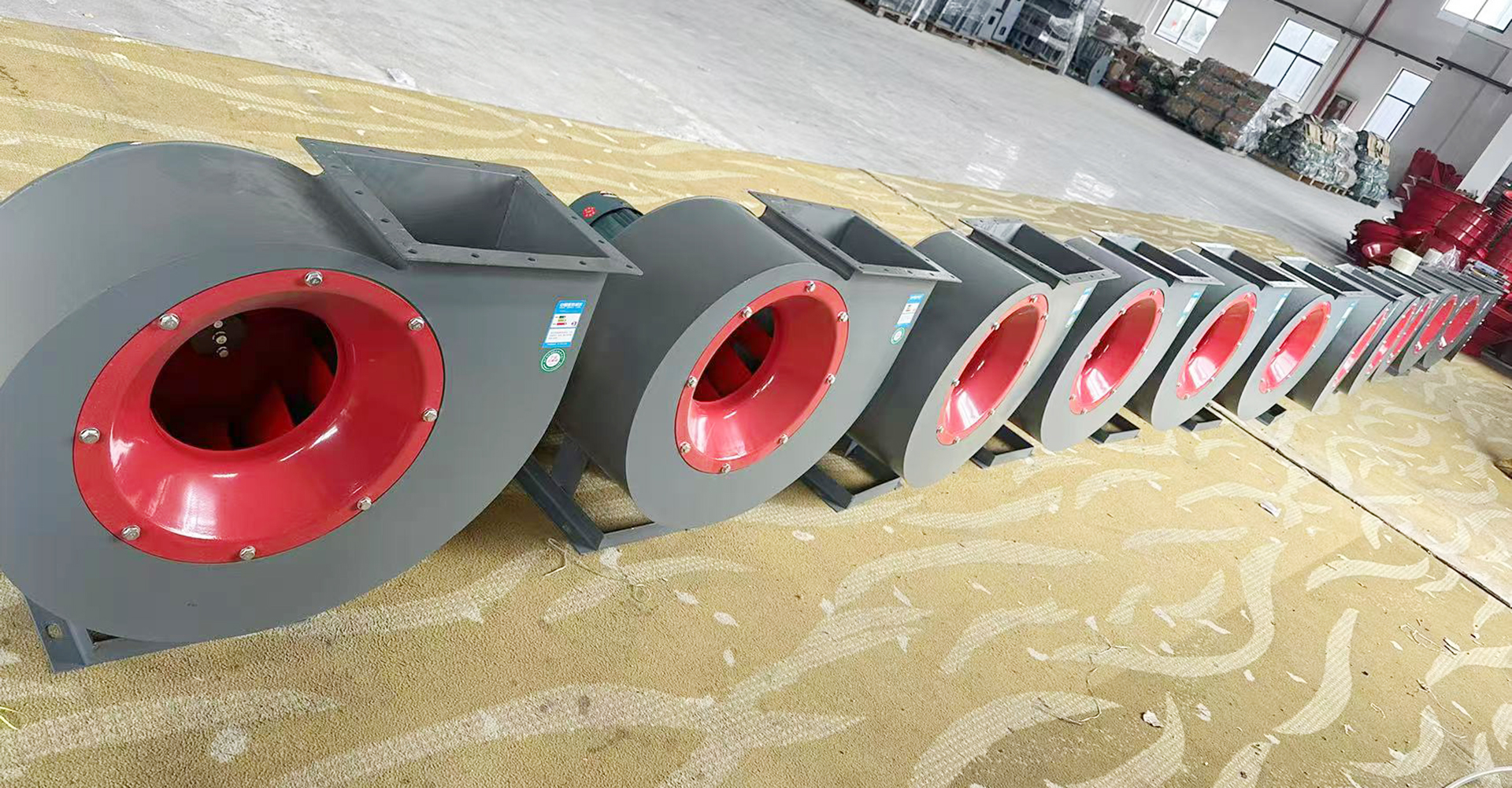

Centrifugal fan is a driven fluid machine, which increases gas pressure and exhausts gas according to the input machinery. Its core function is to convert the mechanical energy output by the motor into gas pressure energy and kinetic energy, and realize "air supply" or "air exhaust".

Centrifugal fans are widely used in factories, coal mines, tunnels, cooling towers, vehicles, ships, building ventilation, ash removal refrigeration, boiler ventilation, industrial kiln ventilation, air conditioning equipment and household electrical equipment refrigeration ventilation, grain drying and selective ventilation.

The high-speed impeller accelerates the gas, then decelerates, changes the inflow, and converts kinetic energy into potential pressure. When the gas passes through the impeller, the gas enters the impeller from the axial direction and then enters the diffuser. In the diffuser, gas affects the inflow, increases the area of the pipe section, slows down the rotation and converts kinetic energy into pressure energy.

The key to the pressure increase in the impeller is the expansion process. According to the backflow device, it enters the multistage centrifugal fan. Centrifugal fan is essentially a variable flow and constant pressure equipment.

When determining the speed, the theoretical curve of pressure flow of centrifugal fan should be straight line, which is characterized by bending due to internal loss. The change of inlet temperature or density has great influence on the pressure of centrifugal fan. When the inlet temperature (minimum air density) is high, the pressure is minimum. There are power and flow characteristic curves for a given pressure and flow characteristic curve. When the blower runs at a constant speed, the required power increases with the decrease of inlet temperature.

What are the common faults of centrifugal fans?And what is the coping method?

1.Excessive vibration

Clean up the dust on the impeller+calibrate the dynamic balance → tighten the foundation again;

2. Bearing overheating

Change oil/check alignment/replace bearing;

3.High current

Check whether the pipeline is blocked or the valve is not opened to avoid long-term overload of the motor.

So, what are the uses of centrifugal fans?

1. Ventilation and air conditioning system Ventilation of industrial workshops: In large spaces such as production workshops, warehouses and workshops, centrifugal fans are often used in ventilation systems to ensure air circulation, improve indoor air quality and remove harmful gases and dust.

Air conditioning system: centrifugal fan is one of the core components in air conditioning system, which is mainly used for air transportation and ventilation to ensure the effective operation of air conditioning system.

Central air-conditioning: In the central air-conditioning system, centrifugal fans are used for air supply and exhaust to help regulate indoor temperature, humidity and air quality.

2. Smoke and dust emission system Industrial waste gas emission: Centrifugal fans are widely used in industrial waste gas treatment systems to help discharge polluted gases from production workshops into the atmosphere. Through the chimney or exhaust pipe, the fan discharges the exhaust gas to the outside, reducing the harm to workers' health and the environment.

Dust removal system: Centrifugal fan is also used in dust removal system to transport dusty airflow to dust removal equipment to help purify industrial waste gas and reduce environmental pollution.

3. Smoke and gas treatment Boiler ventilation: In thermal energy systems such as coal-fired and gas-fired boilers, centrifugal fans are used to provide air or oxygen, ensure the sufficiency of combustion, and discharge waste gas at the same time.

Combustion system: Centrifugal fans are used for air transportation in various industrial combustion processes, such as iron and steel smelting and glass melting furnace, to help control the temperature and oxygen supply in the combustion process.

4. Gas transportation Chemical and pharmaceutical industries: Centrifugal fans are widely used in gas conveying systems to convey gas, steam or gas-liquid mixtures. The gas conveying, drying and cooling systems in chemical fertilizer, petrochemical and pharmaceutical industries all depend on centrifugal fans.

Gas compression and transportation: for example, transportation and compression of natural gas, air, nitrogen and other gases. Centrifugal fan ensures gas flow and pressure stability through high-pressure gas conveying system.

5. Cooling and freezing system Cooling tower: In industrial cooling towers, centrifugal fans are often used to discharge hot air from the cooling tower to keep the temperature of cooling water and ensure the effective operation of the equipment.

Refrigeration equipment: In cold storage, refrigeration unit and air conditioning cooling system, centrifugal fans are used to transport cooling air or refrigerant gas to keep the temperature low. 6. Dust control system

Dust suction: In mining, steel, mechanical processing, paper making and other industries, centrifugal fans are often used in dust control systems to help suck, filter, remove dust and discharge clean air.

Sand, gravel and mineral treatment: Centrifugal fans are also used in the mining industry to help transport and treat materials such as dust and particles to prevent environmental pollution and workers' health problems.

7. Hot air system Dryer and drying system: In food processing, chemical industry, wood processing and other industries, centrifugal fans are often used in drying equipment to accelerate the evaporation of water by providing hot air.

Hot air circulation system: In some industrial heating equipment (such as furnaces, baking furnaces, etc.), centrifugal fans are used to provide hot air to ensure the uniform distribution of heat and improve heating efficiency.

8. Air compressor system Air compressor: Centrifugal fans also play a vital role in compressed air systems, especially in systems requiring atmospheric flow, to generate high-pressure airflow.

9. Clean room and purification system Clean room ventilation: In high-tech industries such as electronics manufacturing, semiconductor production and biopharmaceuticals, centrifugal fans are used to clean indoor air circulation, keep indoor air clean and prevent pollution sources.

Air flow adjustment: In some strict dust-free environments, fans are used to adjust the air flow direction and pressure to ensure the air quality meets the production requirements.

10. Power industry Power plant ventilation system: centrifugal fans are used in boiler system, ventilation system and exhaust gas emission system in thermal power plants to ensure the normal operation of equipment and effectively discharge exhaust gas.

Air-cooled generator cooling: In the cooling system of power equipment such as generators and transformers, centrifugal fans are used to provide cooling air to prevent equipment from overheating.

11. Cement and mining industries Material conveying: In the process of cement production, centrifugal fans are used to convey coal powder, mineral powder and other materials, and are used in the drying process of materials.

Mine ventilation: Centrifugal fans are often used in mine ventilation systems to ensure air circulation in mines, provide fresh air and discharge harmful gases.

12. Food and beverage industry Ventilation of food processing plants: centrifugal fans are used in the ventilation system of food processing plants to prevent the spread of odor and ensure the hygiene of the production environment.

Drying and baking: Centrifugal fans are often used to provide the required air flow during the baking and drying of food.

Centrifugal fans are widely used in industrial fields because of their advantages of effectiveness, durability and stable flow. They are used in many important links, such as ventilation, waste gas discharge, gas transportation, cooling and drying, which ensure the effective operation of various industrial production systems, improve the working environment and enhance production efficiency.