The role of the linear displacement sensor in the upgrading of automation equipment

The role of linear displacement sensor in the upgrading of automation equipment

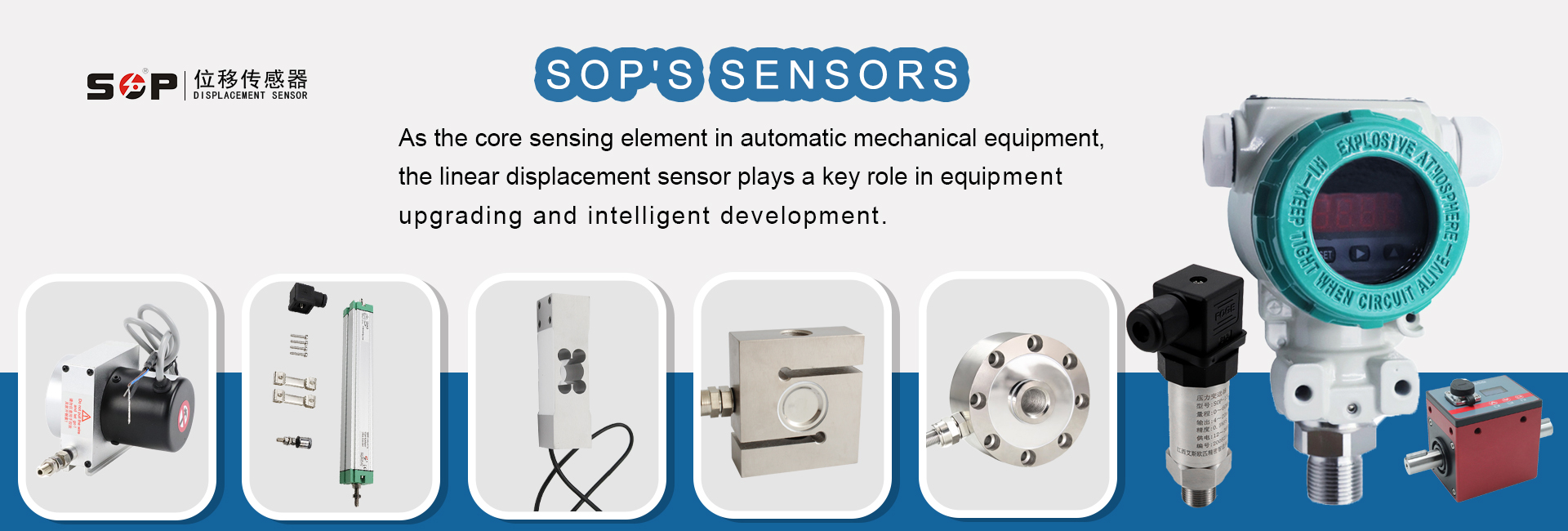

Automation equipment is not only a tool, but also a core engine to promote the transition of human industrial civilization from "age of steam" to "intelligent era". Its function is not only reflected in the improvement of production efficiency, but also profoundly affects industrial structure, economic model and even social development. The development trend of automation equipment includes improving accuracy, efficiency and intelligence, so the linear displacement sensor, as the core sensing element in automation mechanical equipment, plays a key role in equipment upgrading and intelligent development.:

1. Improve the accuracy and stability of the equipment: the linear displacement sensor detects the displacement of mechanical moving parts in real time to ensure the repeated positioning accuracy of the equipment at micron level or higher, and automatically compensates the mechanical transmission error by feeding back the linear displacement data in real time to improve the processing consistency.

2. Enhance the control capability of the equipment: the linear displacement sensor is the basis of closed-loop control, and the feedback displacement data provides real-time position feedback for servo system and PIC control, so as to realize accurate closed-loop control of speed and position. In the coordinated movement of multi-axis complex mechanical system, the linear displacement sensor of each axis is monitored by multi-sensors to ensure the coordination of multi-degree-of-freedom movement and the normal operation of the equipment.

3. Promote intelligent and data-based upgrade: through long-term monitoring of displacement data changes, analysis of equipment wear and tear, failure early warning and maintenance planning are realized, which greatly reduces sudden equipment failures. At the same time, combined with industrial Internet, displacement data are uploaded to the cloud for analysis of production rhythm and optimization of movement path.

4. Improve the reliability and prolong the service life of the equipment: under special conditions of high temperature, oil pollution and vibration, accurate control and wear detection are realized through automatic calibration or compensation of the linear displacement sensor, which ensures the long-term stable operation of the equipment.

The linear displacement sensor has become the core technical support to achieve high precision, high efficiency and high reliability in the upgrading of automation equipment through the closed loop of accurate sensing, real-time feedback and intelligent decision-making. With the advancement of industrial intelligent manufacturing, its deep integration with AI technology will further promote the development of equipment in the direction of intelligent upgrading!