Ultrasonic flow meter SOPSWU801

Ultrasonic flow meter SOPSWU801

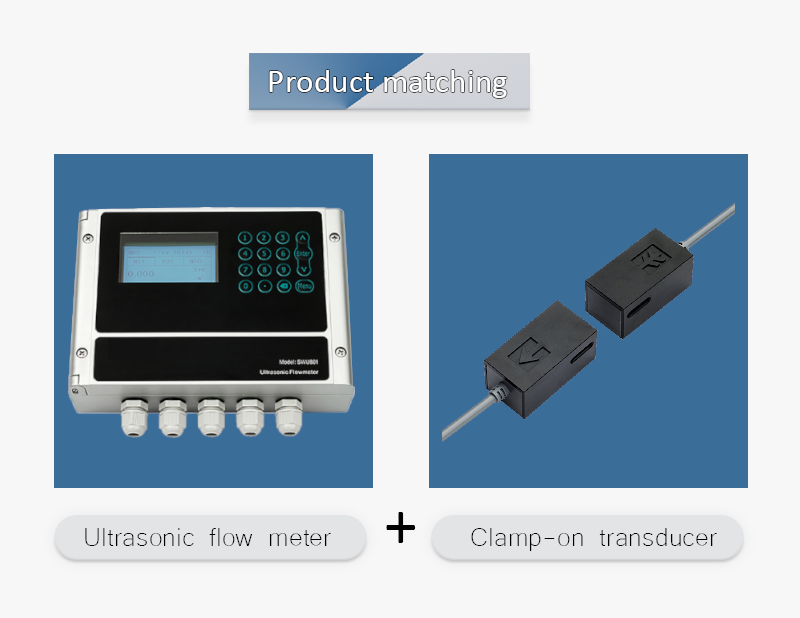

Ultrasonic flow meter SOPSWU801 is a fixed ultrasonic flow meter host, which is installed on the wall and suitable for long-term online flow monitoring. The host computer is responsible for signal processing, data calculation and communication output, and needs to cooperate with ultrasonic sensors (external clamp/plug-in) to form a complete measurement system.

Its main features are as follows:

1. Industrial shell: metal material, IP65 protection level, suitable for harsh industrial environment.

2. LCD backlight display screen: display instantaneous flow rate, cumulative flow rate, flow rate and other parameters.

3. Matrix keyboard operation: Touch keys to support parameter setting and menu navigation.

4. Multi-interface design: cable connector, supporting sensor, power supply and signal output connection.

The advantages of this ultrasonic flow meter mainly include:

1. Non-contact measurement (external clamp) No damage to the pipeline: the sensor is attached to the pipe wall, and there is no need to cut the pipe and open the hole, which will not affect the production.

Zero pressure loss: no interference with the flow field and no energy loss, especially suitable for energy-saving metering of large-diameter pipelines.

Widely used: supporting DN15~DN6000mm pipe diameter, metal/nonmetal pipes (steel, stainless steel, PVC, cement pipes, etc.).

2. High accuracy and stability

Measurement accuracy: 1% reading (flow rate > 0.2m/s) with repeatability of 0.2%. Sampling frequency: up to 300 times per second (FPGA chip processing), quick response.

Anti-interference: Double-balanced signal differential transmitting/receiving circuit, which can resist the interference of frequency converter and high-voltage line.

3. Multifunctional integration

Two-way measurement: automatic identification of forward/reverse flow and calculation of net cumulative flow.

Heat metering: PT100 temperature input is optional to realize BTU metering.

Data recording: automatically store historical data.

4. Convenient installation and maintenance

Wall-mounted design: the main machine is fixed on the wall or instrument cabinet to save space.

External sensor: no need to stop the flow during maintenance, which reduces the operation and maintenance cost.

Chinese and English menu: friendly operation interface and simple parameter setting.

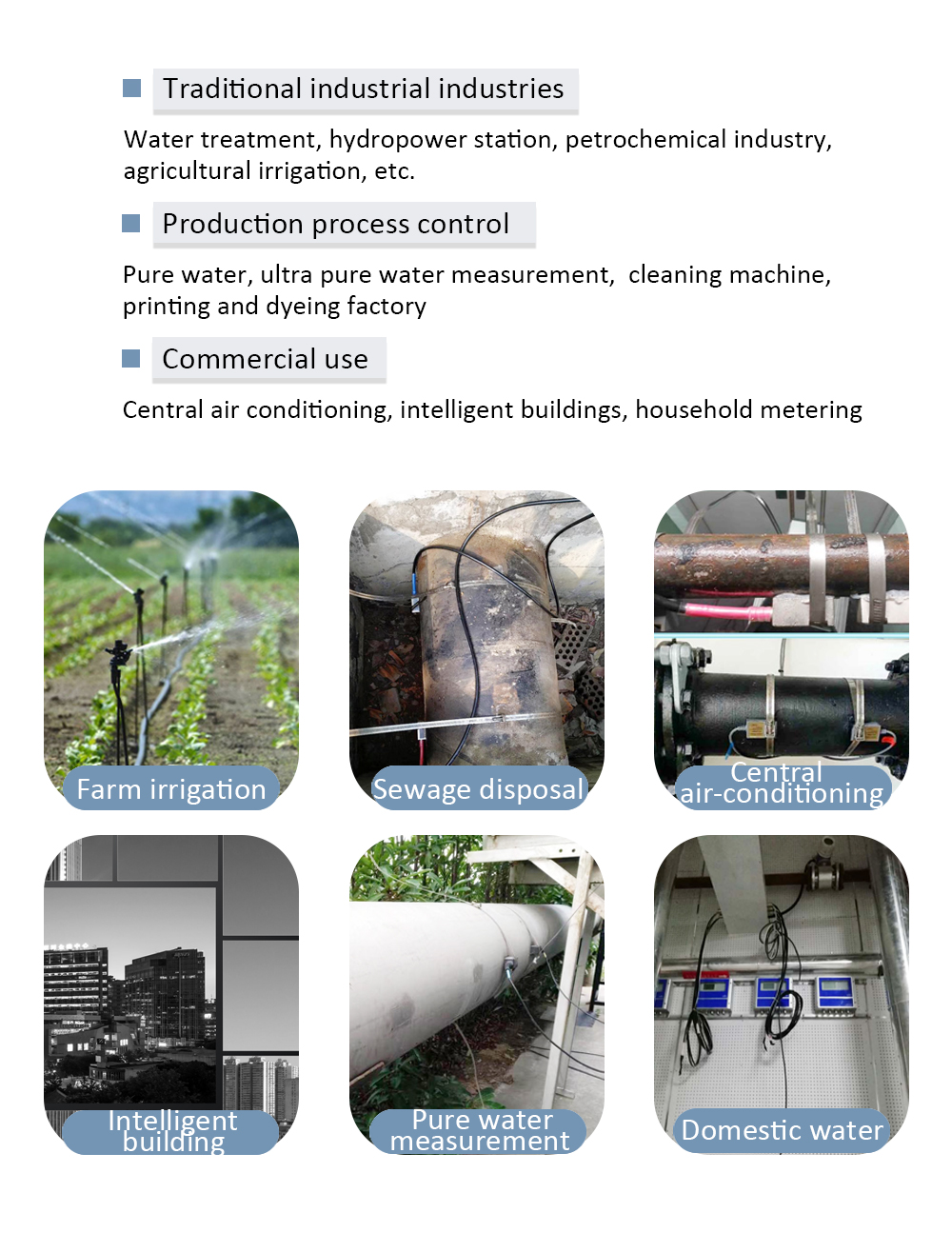

Typical application scenarios of this ultrasonic flow meter SOPSWU801 mainly include:

1. Municipal Water Affairs and Water Supply and Drainage DMA partition metering of water supply network: minimum flow monitoring at night to accurately identify leakage areas Optimization of pumping station scheduling: real-time monitoring of main pipe flow, reducing energy consumption of pumping stations by 15-30%. Sewage treatment: monitoring the inflow and outflow of water and calculating the treatment load.

2. Energy and heating system District heating pipe network: hot water flow measurement, combined with temperature to realize heat charging (instead of traditional mechanical heat meter) Central air conditioning system: chilled water/cooling water balance adjustment to optimize the efficiency of the main engine. Thermal power plant: trade settlement of steam and hot water flow

3. Petrochemical industry Long-distance pipeline of refined oil: trade-grade metering (accuracy 0.5%), saving energy consumption of pumping station without pressure loss. Chemical process control: flow monitoring of corrosive liquid (acid-base solution) and high-viscosity polymer. Oil and gas fields: flow measurement of water injection and polymer flooding.

4. Environmental protection and water treatment Sewage discharge monitoring: joint monitoring of total discharge of enterprises and COD/ ammonia nitrogen. River/channel flow: supporting open channel weirs and troughs to realize the measurement of non-full pipe flow. Agricultural irrigation: accurate measurement of irrigation water quantity in open channels and pipelines

5. Food, Medicine and HVAC CIP cleaning system: verify the flow of cleaning solution to ensure the cleaning effect. Pharmaceutical water: purified water and water for injection (WFI) are measured and meet GMP/FDA requirements. Building automation: air conditioning water system flow distribution, energy household billing.

6. Industrial process control Hydraulic system: high-pressure oil cylinder flow monitoring (pressure resistance can reach 155Bar) Cooling water circulation: monitoring the cooling water flow of injection molding machine, air compressor and electric furnace.

Boiler feed water: accurate control of steam boiler makeup water flow

Selection suggestion:

1. Newly-built water supply network: recommended external clip-on +4G remote transmission, battery-powered and 10-year battery life.

2. Renovation of old pipelines: external clamp type (no need to stop water supply) to solve the problem of limited installation space.

3. High-temperature steam/hot oil: plug-in high-temperature sensor with temperature resistance of 200℃ and pressure resistance of 35MPa.

With the characteristics of non-contact measurement, high precision, multi-function and easy integration, this wall-mounted ultrasonic flow meter has become a universal solution in the field of industrial flow measurement, especially suitable for modern water and energy management systems that need long-term stable operation, maintenance-free and remote monitoring.