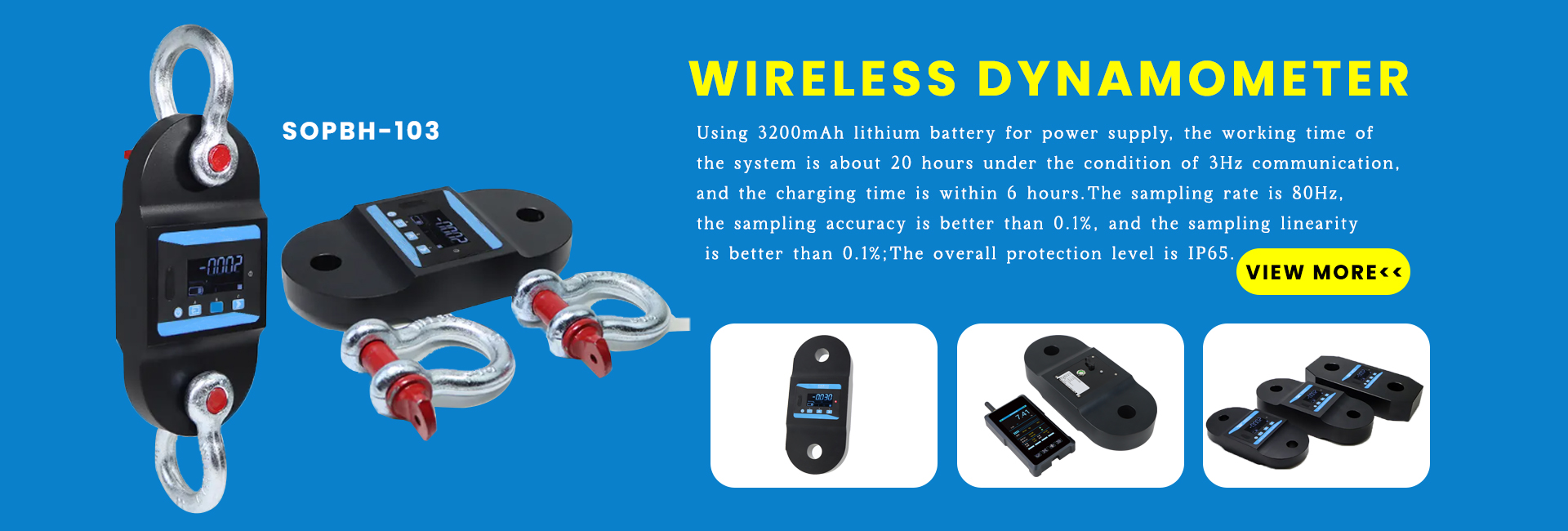

Wireless plate-ring dynamometer SOPBH-103

Wireless plate-ring dynamometer SOPBH-103

The wireless plate-ring dynamometer is a portable device widely used in the field of industrial force measurement. Its core advantages are wireless transmission, high precision and versatility. The following are specific application scenarios, precautions and fault maintenance methods:

一、 the main application areas:

1. Port ship hoisting

It is used to measure the bearing capacity of lifting equipment such as slings and cables to ensure the safety of ships and heavy objects.

2. Wind crane

In the installation and maintenance of wind power equipment, the crane load is monitored in real time to ensure the construction safety.

3. Cable tension test

It is suitable for electric power, communication and other scenes to detect the tension of cables during laying.

4. Industrial production line

Used for product quality inspection, such as measuring product weight or tensile strength of materials.

5. Ship maintenance and safety monitoring

Monitor the tension of anchor ropes and cables to prevent potential safety hazards of ships during berthing or sailing.

二、 the core advantages

1. Wireless transmission and portability

Support real-time data transmission, the operator can remotely monitor through the receiver, and the equipment is light and easy to carry.

2. High-precision measurement

The measurement accuracy can reach 0.05%, and the measuring range covers 5 tons to 200 tons, meeting the needs of different scenes.

3. Multifunctional design

Equipped with peak hold and automatic delay release modes, it supports data storage and unit switching.

三、 the operational considerations

1. Calibration and environmental requirements

Before use, it is necessary to calibrate the equipment to avoid vibration and electromagnetic interference, and ensure the stability of the ambient temperature.

2. Correct installation and reading

When measuring, it is necessary to ensure that the measured object is consistent with the axis of the dynamometer and the line of sight is perpendicular to the scale to reduce the error.

3. Safety operation specifications

Avoid overloading, maintain the equipment regularly, and the operators need to be trained. Through the above applications and specifications, the wireless plate ring dynamometer can effectively ensure the accuracy of industrial production and safety monitoring.

四、 the fault maintenance method

1. Select the appropriate range. Leave as much margin as possible, and oversize measurement is one of the main causes of dynamometer damage.

2. Avoid contact with acid, alkali gas or fluid. The national standard requires that the accuracy index should be guaranteed when the environmental humidity is less than or equal to 90%. For dynamometer without special treatment, the circuit parameters may change and even the circuit may be destroyed. For the above use environment, products with waterproof performance can be used.

3. Minimize the collision of dynamometer. Even if the sensor of dynamometer adopts anti-collision limit measures, excessive collision force will damage the sensor, thus affecting the measurement degree of dynamometer.

4. Regular maintenance. The accuracy of dynamometer may change due to the influence of use, environment and aging of devices. According to the requirements of national metrological technical regulations, regular verification should be carried out. It cannot be used without verification or beyond the effective date of verification.