Working Principle of Draw Wire Sensor

Working Principle of Draw Wire Sensor

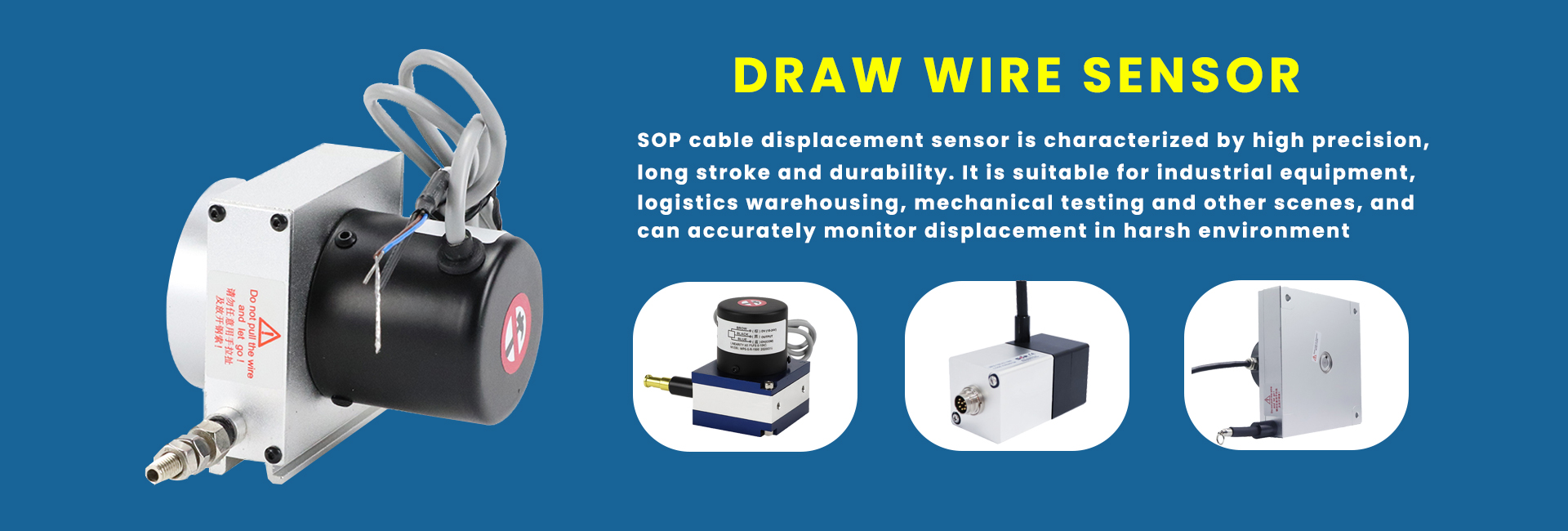

Draw wire sensor is also called rope ruler and rope encoder. Its working principle is very simple, that is, the wire rope at the outlet of the sensor is pulled, in which the wire rope is wound on a pulley built in the sensor. When the wire rope is pulled, the other end of the sensor is connected to the mechanical motion, and a display is installed on it to convert the mechanical motion into an electrical signal to obtain the required data. In operation, the pull rope displacement sensor is installed at a fixed position, and the pull rope is tied to the moving object. The linear motion of the pull rope is aligned with the motion axis of the moving object. When the movement occurs, the rope stretches and contracts. An internal spring ensures that the tension of the pull rope is constant. The threaded hub drives the precision rotation sensor to rotate, and outputs an electrical signal proportional to the moving distance of the pull rope. The displacement, direction or velocity of the moving object can be obtained by measuring the output signal. Commonly used parameters include measuring stroke, output signal mode, linearity, repeatability, resolution, wire diameter specification, outlet tension, maximum round-trip speed, weight, input resistance, power, working voltage, working temperature, vibration, protection level, etc.

Application: The pull rope displacement sensor is especially suitable for linear guide rail system, hydraulic cylinder system, testing machine, telescopic system (forklift, press, elevator, pipe bender, bender, etc.), crane or cable winch, reservoir dam protection system, gate opening control system, testing machine pressure machinery, hydraulic universal experimental machinery, storage position positioning, pressure machinery, paper-making machinery, textile machinery, sheet metal machinery, packaging machinery, printing machinery. Construction machinery, horizontal controller, construction machinery, industrial robot, injection machine, woodworking machinery, elevator, air compressor/hydraulic press, height machine, X-Y axis and other length displacement, etc., dimension measurement and position control, especially suitable for the control of electro-hydraulic servo hydraulic universal testing machine.