-

09-04 2025

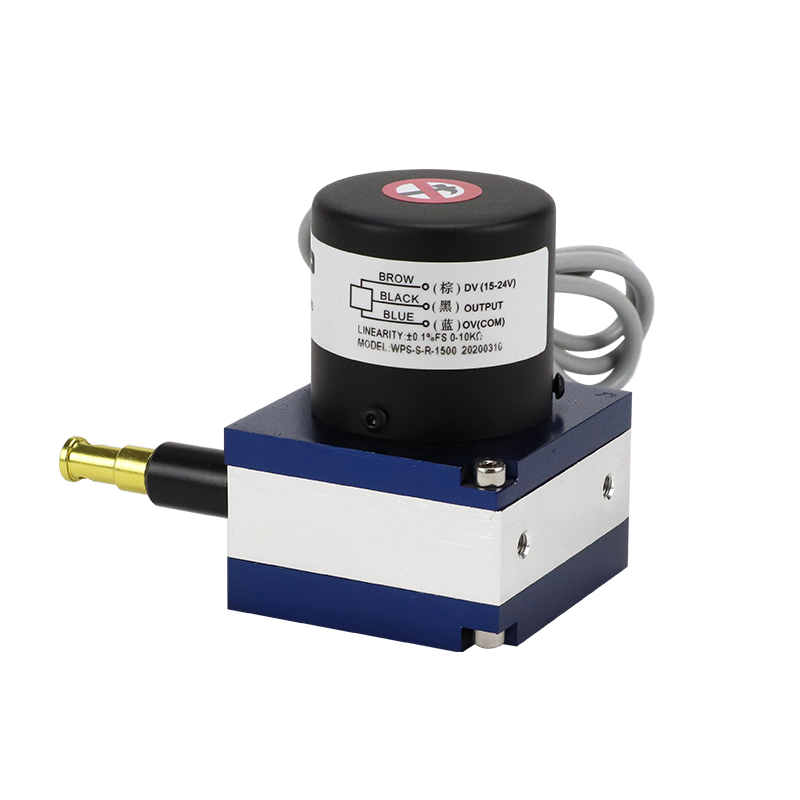

Working Principle of Draw Wire Sensor

Draw wire sensor is also called rope ruler and rope encoder. Its working principle is very simple, that is, the wire rope at the outlet of the sensor is pulled, in which the wire rope is wound on a pulley built in the sensor. When the wire rope is pulled, the other end of the sensor is connected to the mechanical motion, and a display is installed on it to convert the mechanical motion into an electrical signal to obtain the required data. In operation, the pull rope displacement sensor is installed at a fixed position, and the pull rope is tied to the moving object. The linear motion of the pull rope is aligned with the motion axis of the moving object. When the movement occurs, the rope stretches and contracts. An internal spring ensures that the tension of the pull rope is constant. The threaded hub drives the precision rotation sensor to rotate, and outputs an electrical signal proportional to the moving distance of the pull rope. The displacement, direction or velocity of the moving object can be obtained by measuring the output signal. Commonly used parameters include measuring stroke, output signal mode, linearity, repeatability, resolution, wire diameter specification, outlet tension, maximum round-trip speed, weight, input resistance, power, working voltage, working temperature, vibration, protection level, etc.

-

08-15 2025

How to maintain the pressure sensor in use?

Common pressure sensors include resistance strain gauge pressure sensor, semiconductor strain gauge pressure sensor, positive pressure sensor, inductive pressure sensor, capacitive pressure sensor, resonant pressure sensor, capacitive acceleration sensor, optical fiber pressure sensor and so on. Piezoresistive pressure sensor is the most widely used pressure sensor, which has the characteristics of low price, high precision and good linearity.

-

08-08 2025

What are the classifications of pressure sensors and how to select them?

Pressure sensor is the most widely used sensor, which is used in various industrial automatic control environments, involving water conservancy and hydropower, railway transportation, intelligent building, production automatic control, aerospace, military industry, petrochemical, oil wells, electric power, ships, machine tools, pipelines and many other industries.

-

07-28 2025

Application of LionGoal High Pressure blower in Injection Molding Machine

LionGoal high-pressure blower is widely used in all walks of life Home and abroad, and many customers will express their desire for long-term cooperation after purchasing lionGoal brand. LionGoal high-pressure blower has many applications, among which it can be widely used in injection molding machines. Choosing the high-pressure blower with high cost performance and good performance can greatly help enterprises to improve production efficiency, optimize working procedures and greatly enhance their core competitiveness.

-

07-21 2025

Wireless plate-ring dynamometer SOPBH-103

The wireless plate-ring dynamometer is a portable device widely used in the field of industrial force measurement. Its core advantages are wireless transmission, high precision and versatility. The following are specific application scenarios, precautions and fault maintenance methods:

-

07-15 2025

The Common Faults of Linear Displacement Sensor and Troubleshooting Methods

The working principle of linear displacement sensor is the same as that of sliding rheostat. It is used as a voltage divider, and it presents the actual position of the measured position with relative output voltage.

-

07-10 2025

Do you want to use LVDT displacement sensor in automobile parts inspection?

For the inspection of automobile parts, the size inspection should be the most important, and LVDT displacement sensor (differential transformer displacement sensor) must be used to detect and control the size. As a displacement sensor with strong environmental adaptability, high precision and durability, LVDT displacement sensor is the first choice in parts inspection system. So what is the specific application of LVDT displacement sensor in automobile parts inspection?

-

07-01 2025

The Common Mistakes in the Use of High-pressure blowers

With its advantages of high pressure and low noise, high-pressure blower plays an important role in ventilation and material transportation. However, some misunderstandings in the use process will often affect the performance of the blower and even shorten its service life. The following misunderstandings need special attention:

-

06-25 2025

Theory, Characteristics and Application of LVDT Displacement Sensor

The advantages of LVDT mainly include: non-contact principle, good wear resistance, high resolution, good repeatability, no sliding contact and long service life; Fast response speed; High linearity; Good repeatability; Wide range coverage; Low fault/low power consumption/diversity of input and output; Good dynamic characteristics, can be used for high-speed online detection, automatic measurement and automatic control; Can be used in harsh environments such as humidity and dust; Can work under special conditions, such as high pressure resistance, high temperature resistance, radiation resistance, full-tight soil seal working underwater; It can withstand impact up to 150g/11ms, vibration frequency 2KHZ acceleration 20 g; Small size, low price and high performance-price ratio.

-

06-17 2025

LionGoal blower helps industrial vacuum cleaner

Since 2014, the national pneumoconiosis public welfare organizations have been launched one after another, and pneumoconiosis has become a disease that scares migrant workers. Pneumoconiosis is a systemic disease in which migrant workers inhale productive dust and lime soil for a long time in their professional production and stay in their lungs, resulting in diffuse fibrosis of lung tissue. In some people who are prone to dust, such as the crushing, screening and transportation of ores in mining and metal smelting, the sand mixing and molding of castings in institutional manufacturing, the sand cleaning, sand blasting and electric welding of castings, the mining, crushing, grinding, screening and mixing of building materials, the mining, transportation and textile of asbestos, tunneling and blasting in highway, railway and water conservancy construction, etc., workers will be vulnerable to long-term inhalation of dust.