News

-

02-08 2026

In-Depth Expansion of Weighing Sensor Technology: From Core Principles to Future Frontiers

Beyond traditional classifications and applications, the depth and breadth of weighing sensor technology continue to expand. The evolution of its core technologies and emerging application scenarios jointly sketch a richer industrial landscape.

-

02-03 2026

Linear displacement sensor KPZ

KPZ is a miniature rod-type linear displacement sensor (also known as an electronic ruler/resistance ruler), belonging to the subdivision series of potentiometer-type displacement sensors. It is suitable for use in confined spaces, with excellent linearity and easy installation. Next, let's take a look at its suitable working environment, application scenarios, selection and installation points, and application advantages.

-

01-28 2026

What should be paid attention to when purchasing load cell products?

In scenarios such as industrial automation, logistics warehousing, and food processing, weighing sensors serve as core metrological components, and their quality directly impacts the stability of equipment operation and the accuracy of data. However, the market is filled with a wide range of products, with inferior sensors often attracting buyers with low prices but suffering from material defects and rough craftsmanship, leading to reduced accuracy, shortened lifespan, and even safety accidents. Next, we will systematically analyze the pitfalls to be wary of when purchasing, covering dimensions such as technical principles, material craftsmanship, and performance parameters, to assist you in establishing a scientific selection logic.

-

01-27 2026

How to choose a load cell? Recommendations for suitable models for different weighing scenarios

The sensor range should cover the maximum weight of the object being measured, with a safety margin reserved. For example, when weighing industrial material tanks, the impact load of the material needs to be considered, and the range is usually 1.2-1.5 times the maximum load capacity. If the range is too small, overload may cause permanent deformation of the elastic body; if the range is too large, the resolution will decrease, affecting the accuracy of small weight measurements.

-

01-23 2026

Load Cell Selection Manual: Classification by Structure Type and Application Scenario

In industrial production, logistics warehousing, scientific research, and other scenarios, the accuracy of weighing data directly affects production efficiency and product quality. However, many people often encounter issues such as large measurement errors and shortened equipment lifespan when selecting load cells, due to a lack of understanding of structural type differences and mismatch with application scenarios. This article will provide you with a systematic selection method from two aspects: structural type classification and application scenario adaptation, helping you avoid common selection pitfalls.

-

01-22 2026

Linear Sensors: The Backbone of Precision Measurement

Linear sensors, also known as linear position sensors, are pivotal components in various applications requiring high-precision measurement of linear displacement. These sensors convert linear motion into electrical signals, enabling accurate tracking and control in industries ranging from automotive to robotics. This article delves into the key aspects of linear sensors, including their structure, types, and applications.

-

01-22 2026

Jiangxi SOP participated in the Russian International Trade Rubber Exhibition from January 27 to 30, 2026

Jiangxi SOP Precision Intelligent Manufacturing Technology Co., Ltd. to Showcase Innovative Solutions at Moscow Exhibitions Jiangxi SOP Precision Intelligent Manufacturing Technology Co., Ltd., a leading manufacturer of precision components and intelligent manufacturing solutions, is set to participate in prestigious exhibitions in Moscow, Russia from January 27-30, 2026. The company will be exhibiting at the Moscow Plastics Industry Exhibition (RUPLASTICA) at the Crocus Expo Exhibition Center.

-

01-15 2026

Application of SOP linear displacement sensor in tunnel

Linear displacement sensor is a kind of non-electric measurement sensor which is widely valued and applied at home and abroad at present. It consists of a heat-treated vibrating wire detection element, and a spring with one end connected to the vibrating wire and the other end connected to the sliding pull rod to eliminate stress. With the pull of the sliding pull rod, the spring begins to extend and causes the tension of the vibrating string to increase, and the vibration frequency of the steel string also changes, and the tension is proportional to the extension of the spring. Therefore, the change of displacement can be realized by measuring the tension of the steel string, that is, the change of the vibration frequency of the steel string.

-

01-14 2026

Application of linear displacement sensor in intelligent agricultural machinery matching

Sensor is a kind of equipment that can sense environmental changes and automatically collect, process and transmit data. Intelligent agricultural machinery is mainly integrated in seeders, harvesters and other devices, supporting automatic driving and operation monitoring, and combining sensors and agricultural machinery equipment to realize the automation and intelligence of agricultural machinery operation. For example, using the controllability of sensors to ensure the accuracy of the driving path of agricultural machinery and avoid the collision of agricultural machinery at high speed and damage to agricultural products.

-

01-08 2026

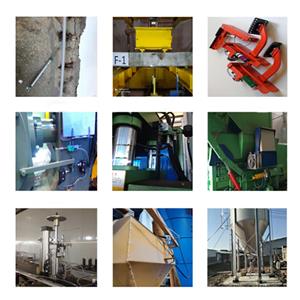

Application of spoke load cell

Spoke force sensor is also the most commonly used sensor in our industrial practice. Because of its advantages of shock resistance, vibration resistance, high precision, high stability and wide working temperature range, it is widely used in many industries. So, how much do you know about the main principles and principles of spoke force sensor structure design? Next, let's understand the main principles and principles of structural design of spoke force sensor. Main principles and principles of structural design of spoke weighing sensor; Spoke force sensor First, the main principles of structural design of spoke force sensor